Barrnon

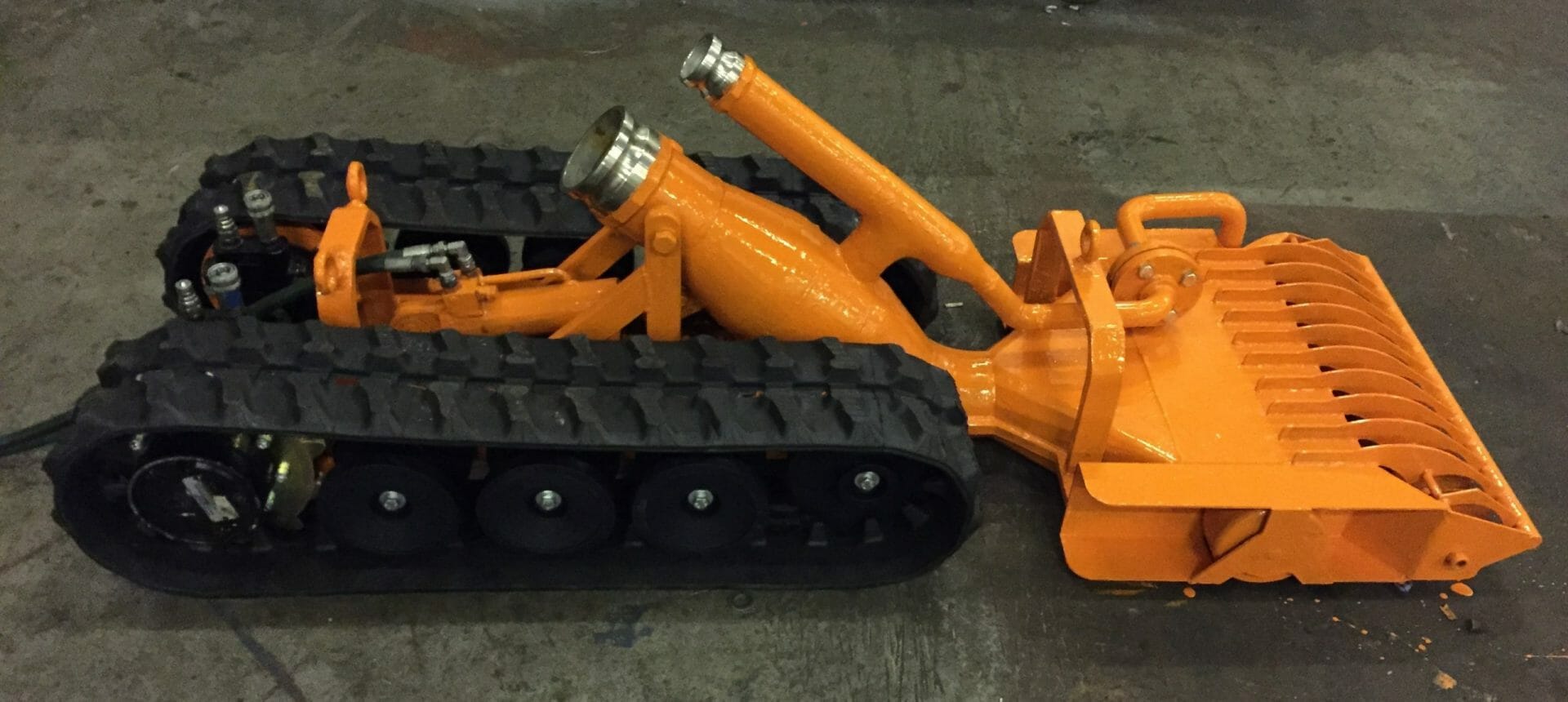

Working in some of the world’s harshest settings calls for a particularly specialised form of engineering. Barrnon designs and manufactures robotic technology for some of today’s most challenging environmental threats. Their projects include the decommissioning of some of the most prominent historical nuclear facilities. Notable examples include the Bladecutter, an active nuclear sludge-waste retrieval unit, and the HydroSpyder, a floating tool-deployment platform that walks on water, using surface tension to deploy tools.

Managing Director Andy Barr established Barrnon in Appleby, Cumbria, in 2007 with the aim of pushing his engineering ideas to the limit. His early work involved marine design, finding success with an exceptionally efficient scallop catch handling system. The last four years has been spent developing a product, which aims to solve one of the world’s biggest problems; how to safely retrieve nuclear waste. As part of this, the company built a 25 metre testing tower to mimic nuclear storage.

During this time, it became clear to the team that a complete engineering solution was required and in 2019 they purchased their first CNC; a Haas VM-3 vertical mould maker. The VM-3 has a 12,000 rpm direct drive spindle, 24+1 side mount tool change and high-speed machining facility for faster cornering.

“Moving to in-house machining was a complete game changer,” explains Andy. “We use it as a 5-axis machine, making all of our bespoke fixtures and tooling and by using our own clamping system and Renishaw measuring equipment. We can have multiple set ups and move our components through to various stations. Compared to conventional machining, it’s like night and day.”

Barrnon quickly followed with a second investment; an ST-35Y turning centre with Y axis, live tooling and barfeeder. “We turn a lot of aluminium parts, from hydraulic valves to structural components. By taking the machining in-house, we’ve made a saving of £1.2 million in the first year and it’s made us so much more flexible. The machines take less of a cut and are faster. For one part alone, on a cycle of 80 parts we’ve saved 280 hours by using our own lathe because we have the live tooling option. We’re in control of our own destiny.”

It is this spirit which has lead the team to collect it’s most significant accolade to date; the Queen’s Award for Enterprise. The most prestigious business award in the UK, it recognises outstanding achievements in the fields of innovation international trade, sustainable development and promoting opportunity. The Queen’s award entry was supported by several clients, including Doug Reid from the US government’s chief technology office, following Barrnon’s work on waste retrieval technology at the Hanford nuclear reserve in Washington state.

Plans are currently in progress to build a new 15,000 m2 facility over eight acres of land near Penrith, including an underground testing facility, R&D and further manufacturing. This major expansion will create 250 new jobs in the area.

Visit Barrnon’s website here: https://www.barrnon.com