Turning Centres

A Turning Centre & CNC Lathe for Every Shop

Haas Automation’s complete line of CNC turning centres and CNC lathes is designed to meet the needs of modern machine shops – now and long into the future.

All the Features and Performance You’ve Come to Expect From a Haas

Haas turning centres and CNC lathes offer a wide range of capabilities, including toolroom lathes, big-bore versions, dual-spindle models, live tooling with C-axis, and Y-axis capability.

Do even more

From Y-axis capabilities to bar feeding solutions, Haas machines offer a toolbox of productivity-boosting options – because there’s no such thing as too much performance.

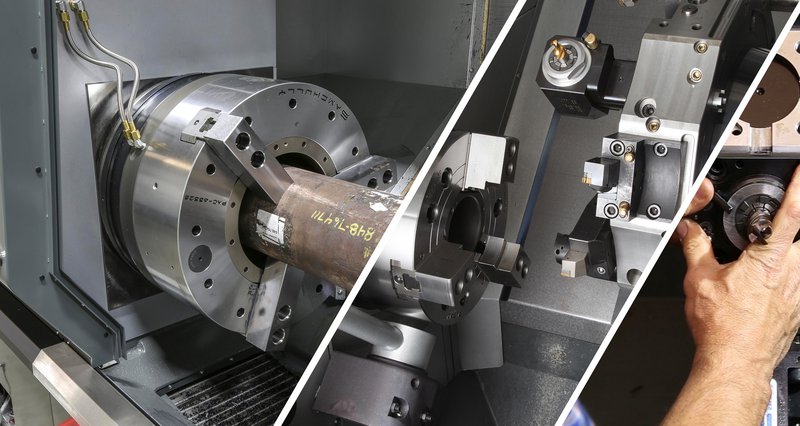

Spindles

Purpose built for Haas machines

Designed and manufactured in California by Haas, these spindles are custom-engineered for power, precision, and durability.

We manufacture all spindles in-house using Haas machines. Mill and CNC lathe spindles are roughed-out on Haas lathes in robotically tended cells. Final hard turning and threading are also completed on Haas machines.

Tool Presetting

Cut your setup time in half

Reduce setup times, work more efficiently, and perform in-process offset updates with the Automatic Tool Presetter.

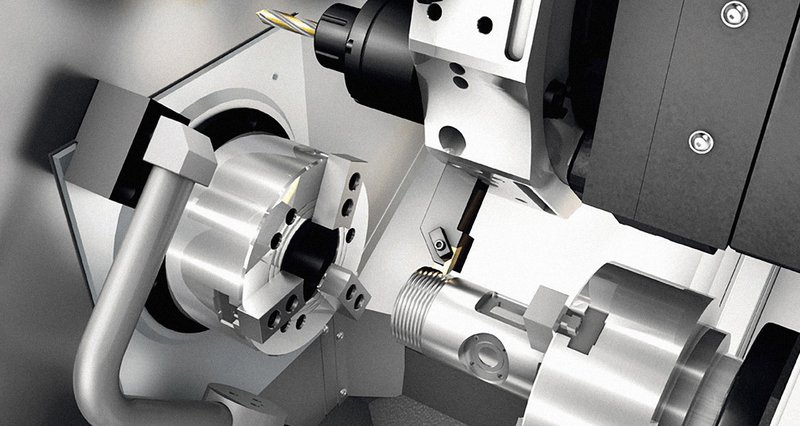

Turrets & Live Tooling

Versatility and performance

Add multitasking capabilities to reduce your setups and increase part accuracy. Customize your Haas lathe with a variety of turrets, or add live tooling to substantially increase your productivity.

Swarf and Coolant

Solutions for all swarf types

Load up your Haas turning centre and CNC lathes with powerful tools for swarf clearing, coolant management, and swarf removal.

Parts come out best when the cutting tool is lubricated, the cutting zone is clear, and your machine is free of chips. We obsess over creating the optimal cutting conditions to produce perfect parts.

With almost 250,000 machines in the field, and more than 300 Haas machines in our own machine shop, there isn’t a chip-management issue we haven’t seen. And our solutions to those issues become features and options on Haas machine tools. Whether you cut steel, aluminum, high-temp alloys, or even non-metallic materials, there’s a Haas system to suit your needs.

The Haas Control

Faster, smarter, and more powerful

The machine tool industry’s most user-friendly control is better than ever, and ready to help you create almost anything.

The Haas control – hardware and software – is designed and built in-house, and optimized specifically for Haas machine tools. If there is a problem – Haas Automation takes full responsibility for the entire machine. The Haas control is easy to learn and use, and it is the same across the entire product line.

Haas machines are also used extensively in educational institutions around the world, so graduating students are already familiar with the Haas control, which makes finding new operators and programmers easier, and simplifies training.

Here’s a link to a video explaining the Haas Visual Programming System

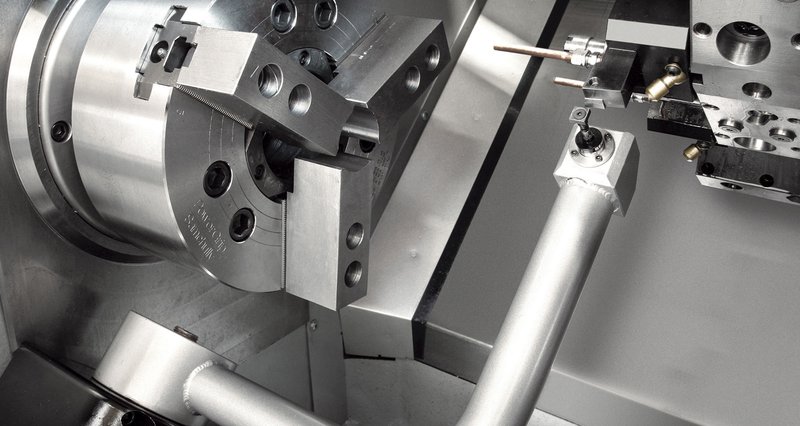

Dual-Spindle Machining

More parts, fewer setups

Multitasking is key to reducing setups and increasing part accuracy. Our dual-spindle, Y-axis lathes provide “done-in-one” machining capability.

Haas DS high-performance spindles provide extreme rigidity and thermal stability. A variety of workholding can be mounted on either spindle optimizing productivity. Optional spindles are available for increased PRM or a larger through-bore diameter for increased bar capacity.

Dual-spindle turning combined with Y-axis and live tooling allow multiple operations in a single setup to reduce part handling and increase accuracy.