Fully Integrated Pallet Pool Systems

High-volume production, unattended operation

Whether you’re doing high-volume production runs, high-mix/low-volume machining, or just want to run lights-out, our fully integrated pallet pool systems can boost your productivity. They integrate seamlessly with the Haas control, which includes a simplified Pallet Schedule Table that allows pallet-scheduling functions from a single dedicated screen.

The pallets can be scheduled individually according to priority and sequencing requirements, allowing high-priority parts to be machined first or staged more often. Completed pallets are returned automatically to the holding location, or can be sequenced to a protected operator station for immediate unloading and re-loading.

- Fully integrated solution for lights-out production

- Easy-to-use scheduling interface in the Haas control

- Dedicated load/unload station

- Must be ordered with the machine

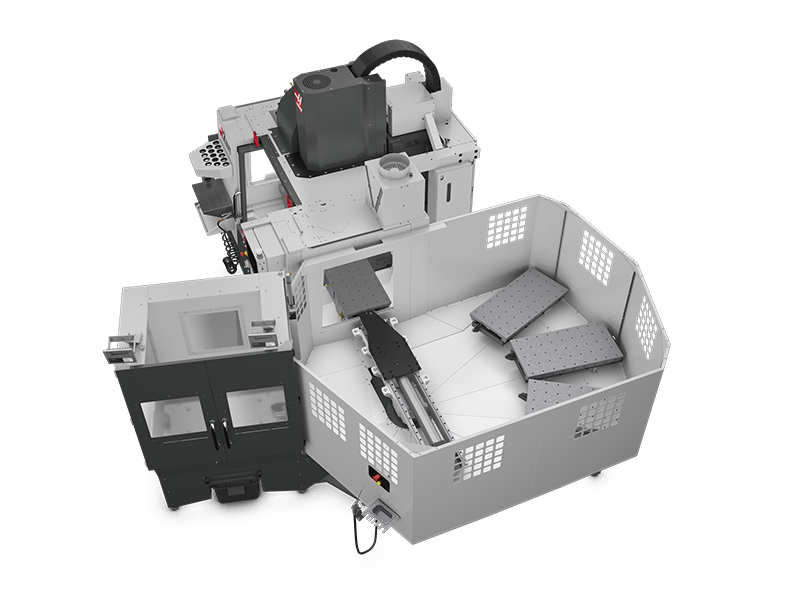

Boost Production on a VF-2YT Series Mill

Have you ever wanted to boost your spindle uptime on your VF-2YT series? The VMC Pallet Pool increases spindle run time and allows for unattended automation so you can run more parts at the end of the day. Using 4 total pallets (1 machining and 3 storage locations), this pallet pool is a must-have for shops looking to boost throughput using the small footprint of the VF-2YT series machines.

3+1 PALLET POOL

High-volume production for the VF-2YT series

Available on these models:

- VF-2YT/SSYT – Work Envelope: 762 mm width x 457 mm depth

- VM-2 – Work Envelope: 762 mm width x 457 mm depth

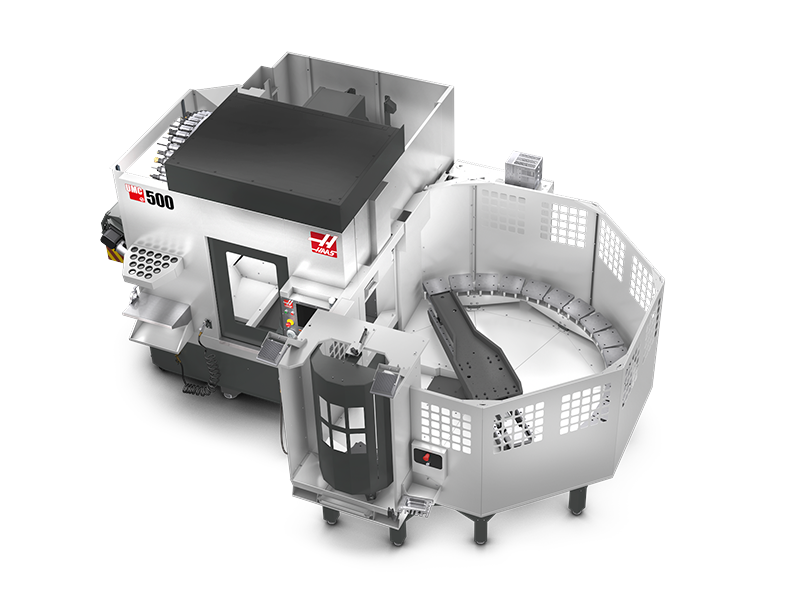

20+1 PALLET POOL

Take your 5-Axis UMC-500/SS to the next level

Available on these models:

- UMC-500/SS – Work Envelope: 203 x 420 mm tall

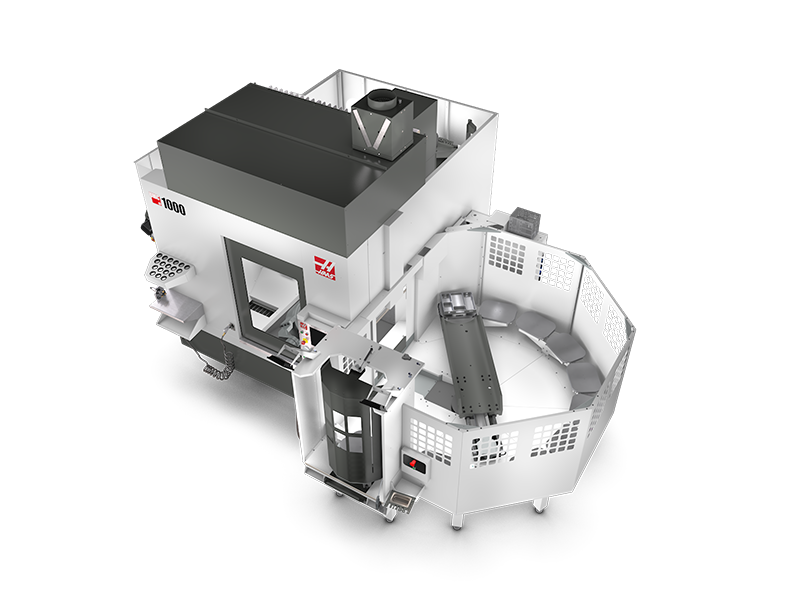

10+1 PALLET POOL

Run your 5-Axis UMC-500/750/1000 unattended

Available on these models:

- UMC-500/SS – Work Envelope: 406 x 406 mm tall

- UMC-750/SS – Work Envelope: 406 x 533 mm tall

- UMC-1000/SS – Work Envelope: 406 x 533 mm tall

6+1 PALLET POOL

Run your 5-Axis UMC-1250 unattended

Available on these models:

- UMC-1250/SS – Work Envelope: 762 x 610 mm tall

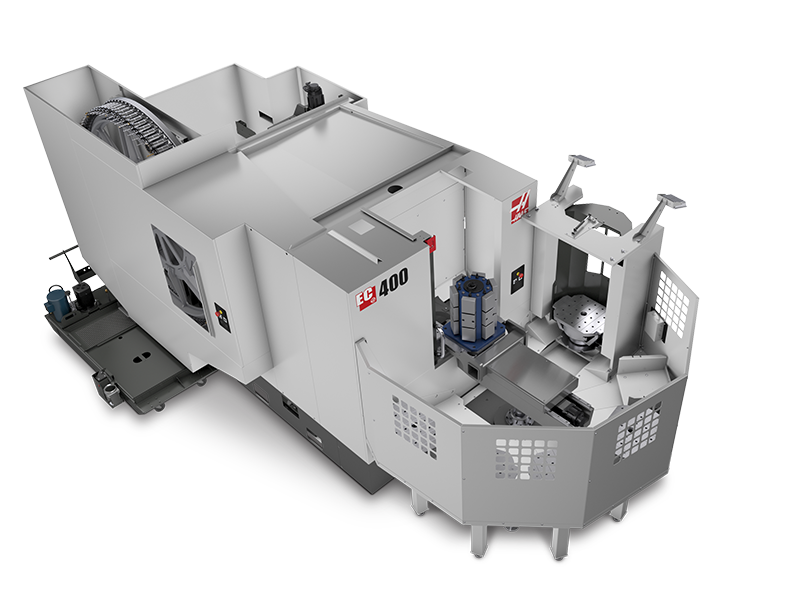

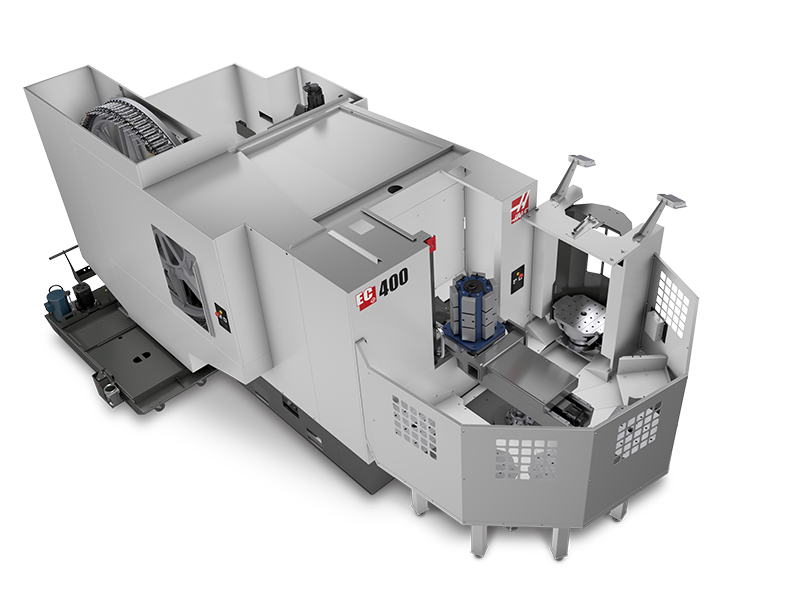

6+1 PALLET POOL

Boost the productivity of your EC-400

Available on these models:

- EC-400 – Work Envelope: 558 x 635 mm tall

AUTOMATION OPTIONS AND CONFIGURATIONS CHART

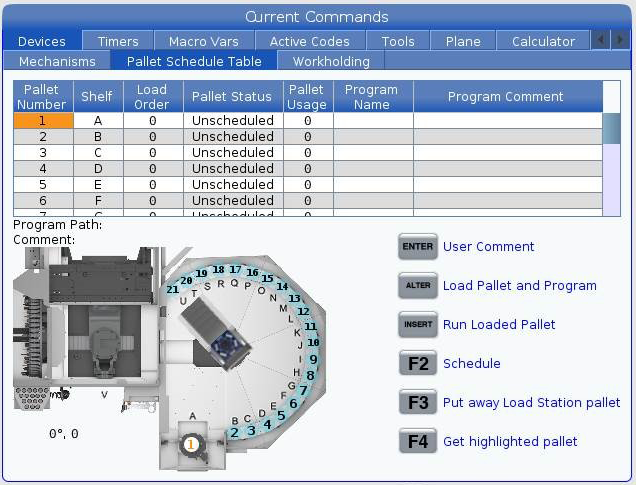

How to use the scheduling table

In this video, Mitchell gives us a thorough walk-through on the ins and outs of scheduling your work on a Haas Pallet Pool system.

Everything you need is easily accessible on one screen on the Haas control, and you’ll find the Pallet Schedule Table is quick to understand and navigate.

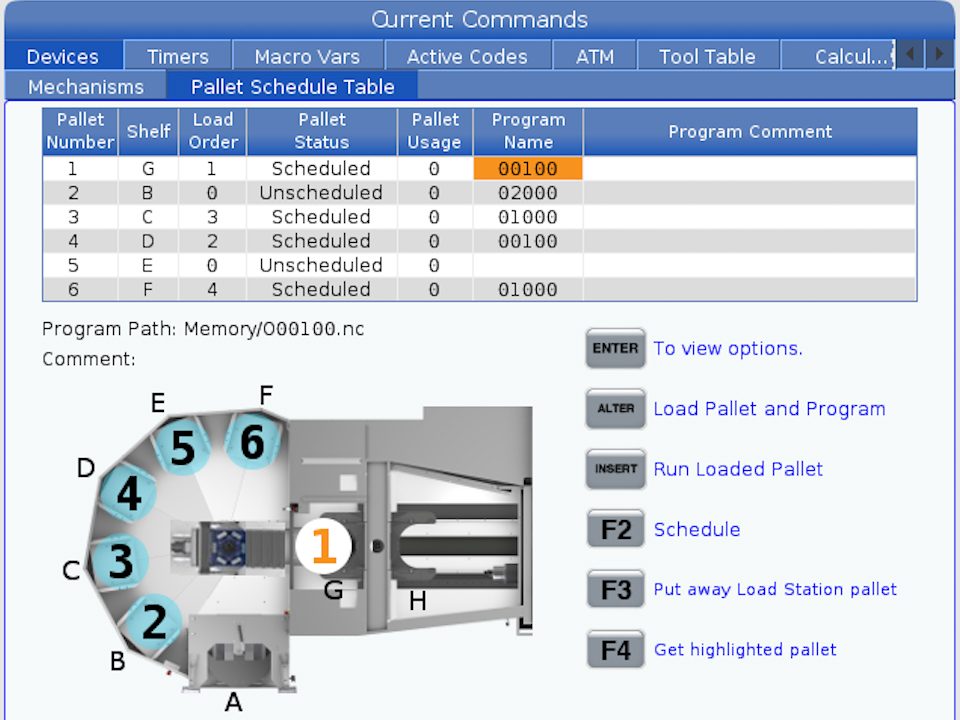

Pallet Schedule Table Interface

The simplified Pallet Schedule Table (PST) controls pallet scheduling functions from a dedicated screen. Pallets can be scheduled individually according to priority and sequencing requirements.

- Each Pallet is identified with a number (1 through 6), and each storage location within the Pallet Pool and machine is identified with a letter (A through H). The storage locations do not change, but the pallet ID numbers move, so you can quickly see where any pallet is at any time. Translucent numbers indicate a pallet’s destination, while the pallet pool is in motion.

- The LOAD ORDER column indicates the scheduled priority of each pallet. Schedule pallets by pressing the Pallet Schedule button at the load station on the pallet pool, by pressing the F2 key while the desired pallet is highlighted on the PST, or by simply entering a number in the LOAD ORDER column for that pallet.

- Highlight the PROGRAM NAME column for a pallet, and press ENTER to navigate the programs list and select which program to run each time that pallet is loaded into the machine.

- One-Touch function keys from the PST simplify common tasks when operating the machine.

- Press ALTER to load the highlighted pallet into the machine and activate it’s designated program.

- Press INSERT to run the active program. This button starts the cycle in “Pallet Mode.” Pallet Mode will interpret an M199 code as: “load the next-scheduled pallet and run its assigned program” (see below).

- Press F2 to schedule the highlighted pallet.

- Press F3 to send the pallet on the Load Station (Shelf A) to an empty station in the pallet pool.

- Press F4 to bring the highlighted pallet to the Load Station (Shelf A).

We developed a new M-code for use with Automatic Pallet Changers.

M199 is typically used at the end of a program. When the program is started by pressing [CYCLE START] in Memory mode, the M199 acts exactly like an M30 (Program End and Reset).

But if the program is started by pressing [INSERT] while the Pallet Schedule Table is displayed (PALLET MODE), the M199 will command a pallet change to load the next scheduled pallet, and then run the program associated with that pallet. This allows the user to start machining on any pallet, even a mid-program start, and continue uninterrupted machining, as long as pallets are scheduled.

DO YOU NEED FUNDING?

TALK TO OUR DEDICATED TEAM

Haas Financial Services can find you the most competitive rates from our extensive portfolio of funders.

CALL SIMON OR TIM ON 01603 227838