Super Speed HSE Verticals

The high-performance VF-4SS HSE and VF-2SSYT HSE vertical machining centres are our best-selling Super Speed machines, and provide the high spindle speeds, fast rapids, and quick tool changes necessary for high-volume production and reduced cycle times. Each SS machine features a 12,000-rpm, inline direct-drive spindle, an ultra-fast side-mount tool changer, and high-speed rapids on all axes.

THE BEST-VALUE, HIGH-PERFORMANCE HIGH-SPEED VMCS AVAILABLE TODAY.

Every HSE machine provides outstanding features at an excellent price. By the same token, there are a wide range of available options to customise your machine to your exact needs. Not to mention all Haas machines are designed and built in California, USA.

HSE Package includes upgraded features:

• 30+1 Side-Mount Tool Changer

• Through Spindle Coolant

• High Speed Machining

• Chip Auger

• Programmable Coolant Nozzle

• Dynamic Work Offsets

• Tool Centre Point Control

• WIPS Wireless Probing

We have these models in UK stock for fast delivery.

Call 01603 760539 for more information

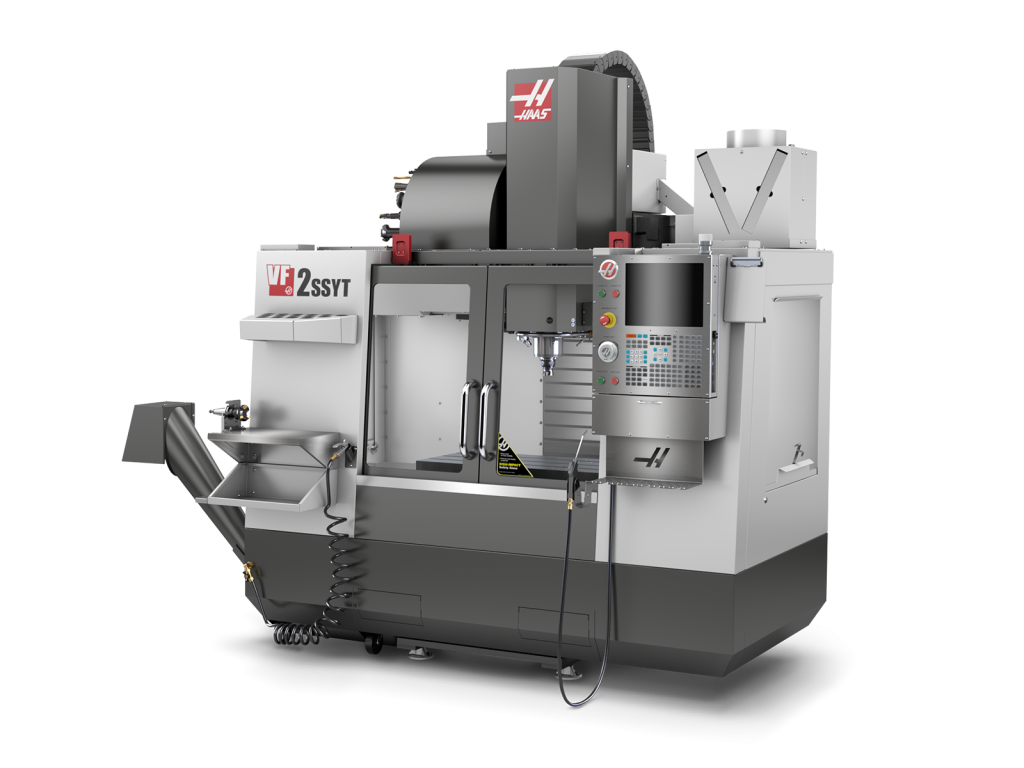

VF-2SSYT

Super Speed VMC-

• 762 x 508 x 508 mm

-

• 12,000 rpm

-

• 30+1 side mount changer

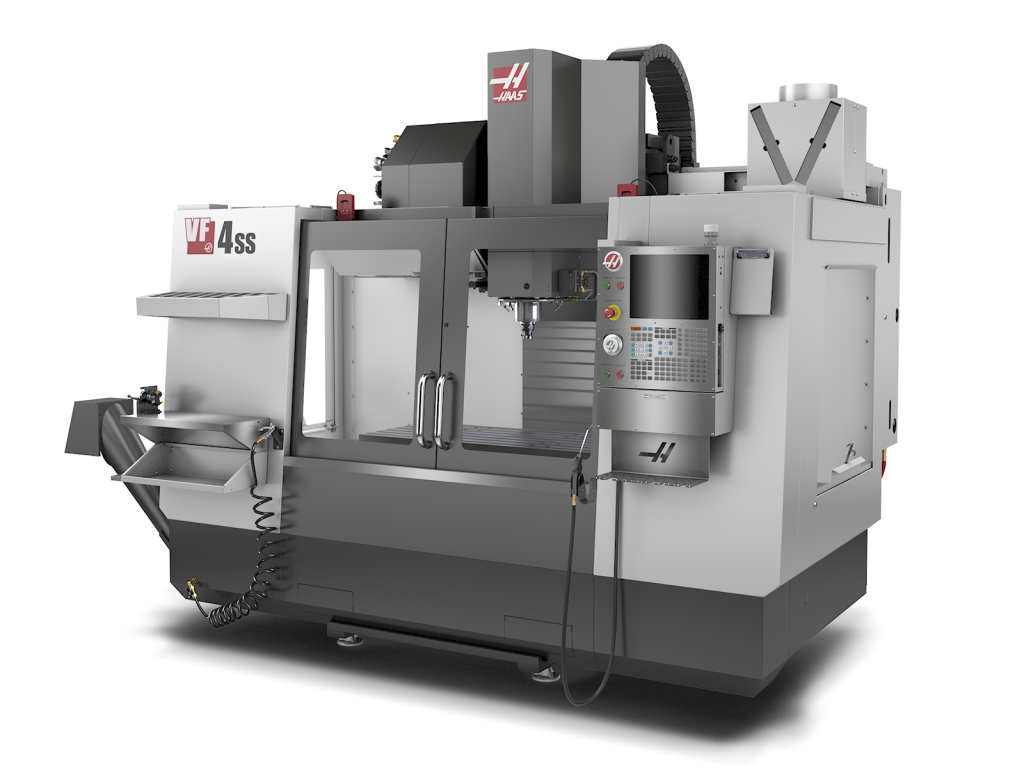

VF-4SS

Super Speed VMC-

• 1270 x 508 x 635 mm

-

• 12,000 rpm

-

• 30+1 side mount changer

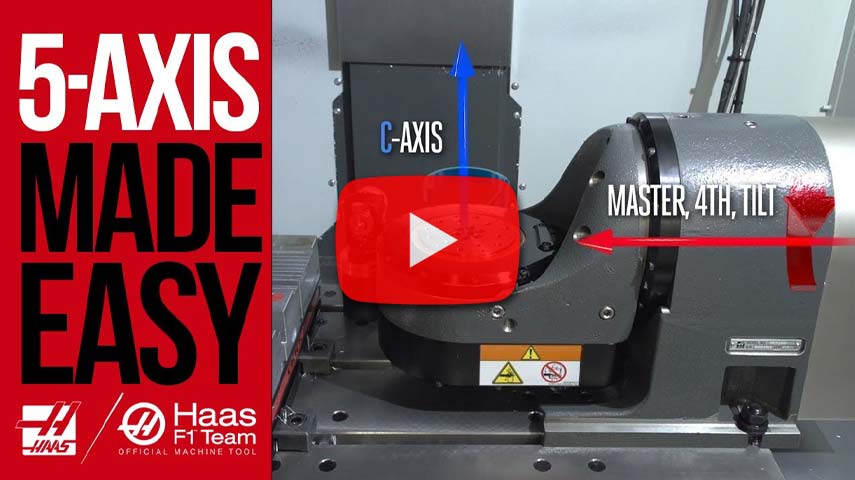

Watch a Haas VF-4SS cutting steel in this demo video. See a part machined from start to finish.

Delivering unrivalled performance at budget friendly prices.