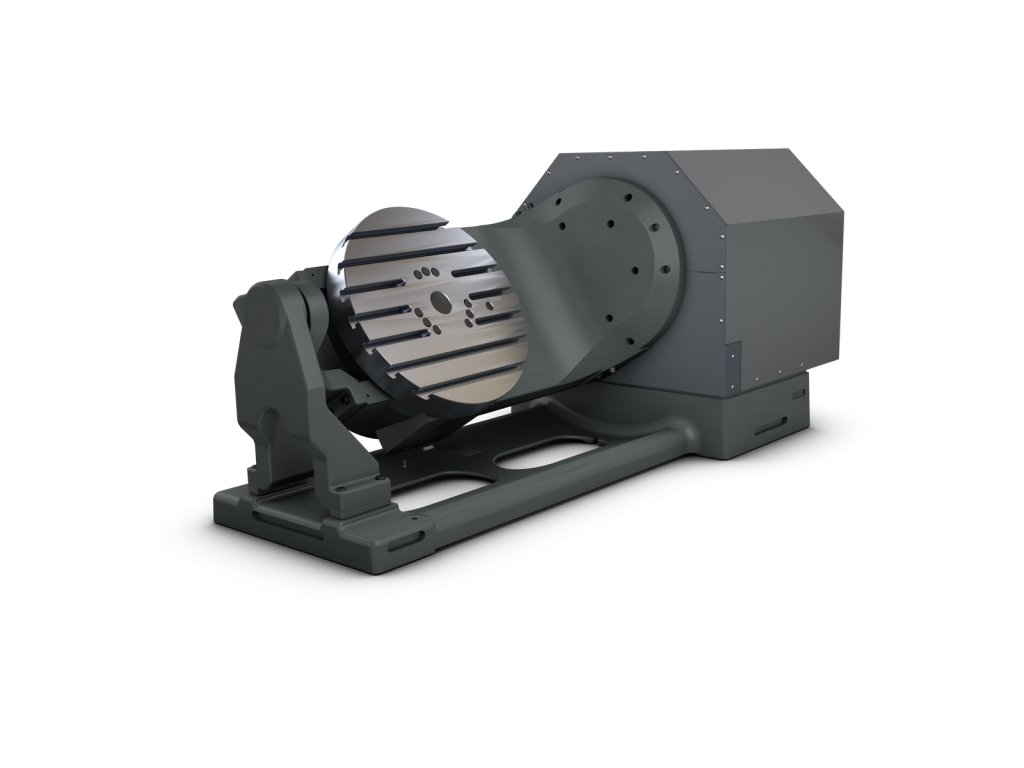

The TR500SS is a high-speed, dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of large parts.

Requires a Haas mill with 4th- and 5th-axis drives, and NGC software version 100.20.000.1110 or later, for true 4th- and 5th-axis operation. Not available for stand-alone operation.

NOTE: Installing the TR500SS on VF-6 through VF-14 VMCs requires the EC8 extended clearance option.

- Add 4- and 5-axis capabilities to your machine

- Easy plug-and-play connection to Haas machines

- Industry-leading performance and capabilities

- Heavy-duty design

- Made in the USA

Haas TR500SS Trunnion Rotary Table

The TR500SS is a high-speed, dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of large parts.

Add serious 4- and 5-axis capability on your machine with a plug-and-play connection to your Haas VF-6 through VF-14 VMC. Get industry-leading performance with this heavy-duty design that’s made in the USA.

DYNAMIC WORK OFFSETS + TOOL CENTRE POINT CONTROL = MAKING 5-AXIS EASIER

Dynamic Work Offsets (DWO) and Tool Centre Point Control (TCPC) are software features in the Haas control. These make setting up 4- and 5-axis jobs as easy as setting up a 3-axis machine. They allow an operator to place the part and fixture anywhere on the machine’s table or platter, regardless of the location that was programmed in the CAM system. DWO and TCPC determine the difference between the centres-of-rotation programmed in the CAM system and the centres-of-rotation within the machine and apply the appropriate offsets.