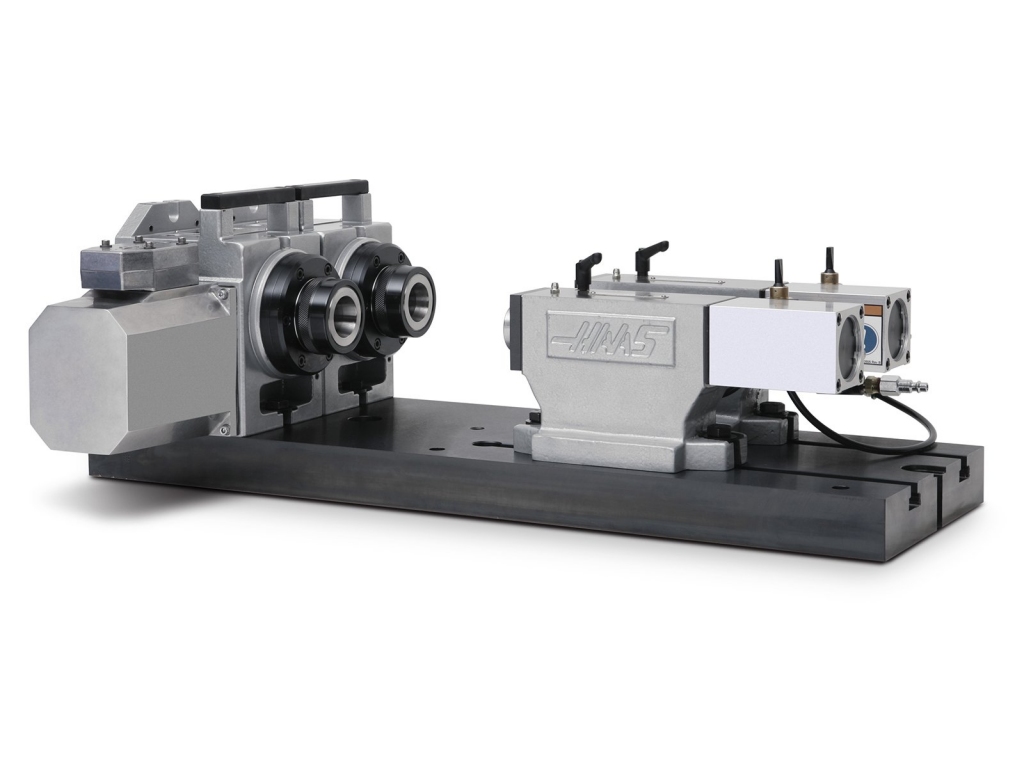

Dual-Spindle Servo 5C System mounted on plate with pneumatic tailstocks. Requires a Haas mill with 4th-axis drive for full 4th-axis operation, or a rotary control box for stand-alone operation. This unit has no collet closing capability as standard. Requires a Haas mill with software version 18.00 or later. Tailstock thrust must not exceed 800 lb (3559 N).

HA2TS

2

SPINDLES

5C

COLLET SIZE

25 ft-lb

MAX TORQUE

200 °/sec

MAX SPEED

Overview

Specs

Video

Resources

HA2TS - Compare to

| HA2TS | ||

|---|---|---|

| tailstock | S.A.E. | METRIC |

| Number | 2 | 2 |

| Type | Pneumatic | Pneumatic |

| Spindle | S.A.E. | METRIC |

| Number | 2 | 2 |

| Max Speed | 0.001 to 200 °/sec | 0.001 to 200 °/sec |

| Max Torque | 25 ft-lb | 34 |

| Nm Nose Thread | 2 3/16" - 10 | |

| Runout Max | 0.0004 " | 0.010 mm |

| Center Height | 5.875 ± 0.002 " | 149.23 ± 0.05 mm |

| Gear Ratio | 60:1 | 60:1 |

| Collet size | std 5C 1/64 - 1 1/16 " | std 5C 0.4 - 27 mm |

| Indexing | S.A.E. | METRIC |

| Max Rotation/Step | 999.999 ° | 999.999 ° |

| Backlash | 50 arc-sec | 50 arc-sec |

| Accuracy (±) | 60 arc-sec | 60 arc-sec |

| Repeatability | 10 arc-sec | 10 arc-sec |

| Worm Gear Dia | 2.8 " | 71.1 mm |

| GENERALS | S.A.E. | METRIC |

| Power Requirement | 115 ± 5% VAC @ 10 A | 115 ± 5% VAC @ 10 A |

| Air Pressure Max | 150 psi | 10.3 bar |

| Operating Temp (max ambient) | 100 °F | 38 bar |

| Duty Cycle (w/o tailstock) | 75 % @ full speed | 75 % @ full speed |

| Weight | S.A.E. | METRIC |

| Brushless Control | 14.2 lb | 6.4 kg |

| Rotary Assembly | 280 lb | 127 kg |

N/A

Manual

SEE OUR ROTARIES IN ACTION

Haas VMCs and Rotary Tables - A Perfect Combination

Take a quick look at just a few examples of how our machine and rotary combinations can help you get your difficult multi-sided parts done better.

Don’t Fear 5-Axis - Parts 1, 2 and 3

Senior applications engineer John Nelson explains why 5-axis machining is much simpler than it has ever been before, and why any shop can be a 3+2 or 5-axis shop.

Learn how the Haas software feature DWO and TCPC (Dynamic Work Offsets and Tool Centre Point Control) makes 4th and 5th-axis work simpler than ever.

Haas VF-2SS & HRC210 Demo

This demo was designed to show off the higher spindle speed and rapids of the VF-2SS and the quickness of the HRC210.

You can also see in-process probing for part location and feature inspection using the Haas WIPS system.

Haas Rotary QuickChange System and Block Fixtures

We’ve touched on the QuickChange and Block accessories available for Haas rotary tables in several of our other videos. This video focuses specifically on those accessories. So if you’re looking to get more productive with your rotary part fixturing, be sure to watch this!