They Build Dreams: The Fender Custom Shop

An American-made Icon (the Fender guitar) made with an American-made Icon (the Haas VMC).

When John Page, co-founder and long-time head of the prestigious Fender Custom Shop, was asked how he could consider bringing a computer-controlled milling machine into a shop with a worldwide reputation for building custom, handmade guitars, he answered simply, “When was the last time you chewed down a tree?”

The retort by Page was not so much a snide remark as it was a realistic observation illustrating how power tools actually are a very vital element in the world of today’s craftsmen. In order to keep final costs somewhat affordable, today’s luthier (guitar builder) is willing to leave the preliminary rough work to more economical, yet accurate, mechanical means.

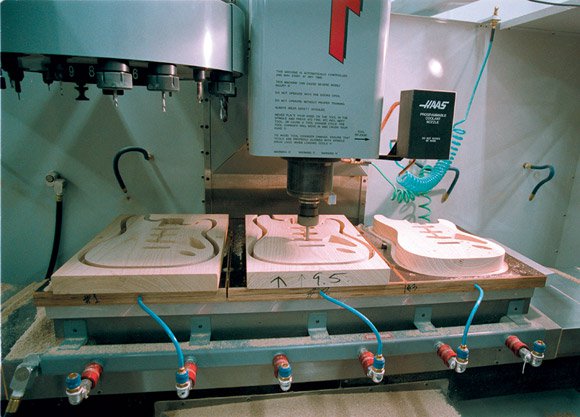

While the word “handmade” does evoke visions of craftsmen chiseling away in a quaint workshop with barely even an electric light, the Custom Shop wing of Fender Musical Instruments is presently cutting guitar bodies and necks on a Haas VF-4 vertical machining center. Although not normally considered a wood cutting machine, Steve Boulanger, head of Fender Custom Shop Engineering and Tooling, saw the Haas CNC as a valuable addition to the productivity and quality of workmanship produced by this elite shop.

In a highly defined market where professional players and collectors demand specific neck shapes and wood types, the use of an extremely accurate CNC milling machine ensures that the master builders receive parts that are pre-cut to exact specifications with absolute programmed repeatability. It is then that these master builders begin working their skills as some of the best and most imaginative luthiers in the world.

A Look at the Fender Custom Shop

Located in an industrial park on the outskirts of the sleepy bedroom community of Corona, the Fender Custom Shop is just a short drive east of Los Angeles on the Riverside Freeway.

Though you would hardly know it from the outside, hidden behind a non-descript door at the back of the building is the guitar player’s idea of a dream factory. A place where – day in and day out – some of the world’s finest master craftsmen and guitar builders meticulously craft custom guitars and basses, and on occasion, even amplifiers. And these one-of-a-kind instruments and art guitars are known worldwide for their incredible tone and beauty.

Steve Boulanger selected the VF-4 because of its versatile cutting abilities and attention to cost and quality. Contrary to popular opinion, Boulanger says cutter speeds need to vary greatly, depending on type of wood and rate of feed — a feature provided by the Haas. With recent efforts to consolidate the Corona Fender production facilities under one roof at the new 177,000-square-foot plant, the Fender Custom Shop had to pare down its square footage while maintaining the ability to produce its specialized product on time and to spec. It is here that the new Haas VF-4, installed in February 1998, has helped enhance the production-to-space ratio by providing a versatile milling machine that can effectively cut three bodies or four necks at a time – and cut them rapidly to exact specifications.

“The Custom Shop needed its own production ability for small-quantity, high-quality guitar and bass guitar wood components, as well as plastic components,” explains Boulanger. “We also make virtually all of our own unique tooling and fixturing. After looking at the CNCs available on the market, we found that the Haas VF-4 had the perfect combination of high quality and low price, plus machine size, ease of use and special features.” He also noted that the way covers seal the ways and ballscrews from wood dust contamination far better than the competitive brands.

It was this economy of space, time and operation, in addition to the unlimited versatility the machine offered in allowing for rapid changes in final cut design – that helped to seal the deal with the Haas sales reps at Machining Time Savers (MTS).

How Much Wood?

When putting together the order for their wood-cutting VF-4 – which was chosen to match the table size with the ability to machine a certain number of guitar bodies or necks in the same setup – the Custom Shop opted for the 10,000-rpm, 20-horsepower vector drive spindle, 1,000-block-per-second processing, macros, Quick Code programming, 3.5″ floppy disc, 4 MB expanded memory, rigid tapping, chip auger, programmable coolant nozzle, remote jog handle, 4th-axis capability, coordinate rotation and scaling, and an Ampro aluminum tooling plate.

“The macro option is a must-have option,” says Boulanger. “When we first got the machine, I must admit that I was a bit baffled by macro programming, but once I understood it, I don’t know how I ever got along without it. The possibilities of macro programming are endless. I am currently re-writing all existing programs to use macros.

“Machining wood to ±.005″ tolerances has its own unique difficulties,” explains Boulanger. “The main problem is that wood swells or shrinks depending on the humidity, causing fit problems day to day. Of course, we try to minimize this by maintaining the shop environment as close to optimum as we can, but different woods absorb and expel moisture at different rates, and the last time I counted we were using 11 or more different species in the construction of our guitars.”

This susceptibility to changes in temperature and humidity has been addressed at the new Corona facility. A sophisticated climate control system maintains temperature within one degree Fahrenheit and humidity within two percentage points, no matter what the conditions are outside. A good way to test this attention to accurate cuts is to try to slide a business card between the side of the guitar neck and the body. On a Fender Custom Shop guitar, it won’t fit. Some cheap guitars have such a large gap that they will accommodate a typical plastic charge card. Do not use your charge card to buy one of these low-quality guitars!

“In addition, due to the 21-tool capacity (20 tools in the changer and one specialized tool mounted to the VMC’s table), we have incorporated many secondary operations, such as fret-slot sawing and face-dot drilling, into the machining cycle, thereby eliminating them in the down-stream process.”

How do you fit 21 tools on a machine with a 20-tool capacity? If you need a special tool like this 90-degree fret-slot saw tool, you just locate it on the table. Now one saw can cut pre-programmed fret slots for any number of neck sizes or designs.

Like the versatile guitar that carries the Fender name – the Stratocaster – the VF-4 was a solution to a set of technical problems, and as such opens new avenues for expansive improvements in design and imagination.

The Birth of the Custom Shop

Although the Fender Custom Shop didn’t officially exist until 1987, the idea surfaced many years earlier. However, the dream did not become a reality until current-day CEO Bill Schultz – who saw the merit of the custom shop concept – selected Page and Texas guitar builder Michael Stevens as the first custom builders. They started small, in an 850-square-foot space near the Corona factory, expecting to build only a handful of instruments a month.

However, when word of the first guitars hit the streets, new orders came pouring in – in numbers far beyond anything the two original builders could handle. It was obvious that the company had tapped into a previously untapped consumer need. In fact, today almost every major guitar manufacturer has a version of a custom shop to satisfy the needs of the elite buyers. But the Fender Custom Shop is still recognized as a leader when it comes to playability and innovation.

Page, who just recently accepted a new assignment as Executive Director of the Fender Museum of Music and the Arts, explains, “We just grabbed a share of the market that I don’t think even we were aware existed, and that’s the market share that wanted the kind of details not available on our production-line guitars at that time, whether it was custom pickguard materials, humbuckers (pickups) or neck shapes.” The Custom Shop grew quickly in space and in personnel, and today boasts more than 60 employees, including the master builders. The Custom Shop is also the location of Fender’s West Coast Artist Relations.

A Hive of Activity

Despite its industrial park surroundings, the Fender Custom Shop today is a veritable hive of craftsmen busily hand-building a wide range of guitars; experimenting with colors, finishes and electronics; and carefully measuring and fine-tuning dimensions. It is here that the Haas VMC has earned a place in a world usually reserved for those long trained in the art of guitar making.

At one workbench, master builder Stephen Stern meticulously shapes the ebony tailpiece of a Fender D’Aquisto archtop guitar. In another alcove, master artisan/woodcarver George Amicay is at work carving on a Stratocaster called “The Roots of Rock,” which is imbedded with 100 etched stones – each carrying the name of one of the greats of rock and roll. In still another corner, master builder Alan Hamel fine-tunes a radical guitar and amp combo he calls “The Hot Rod Set,” a custom pearl-blue Stratocaster with remote-controls that allow the player to tweak the amplifier settings while playing elsewhere on stage. The antennae on both the guitar and amplifier are electronically raised and lowered on command. In keeping with the hot-rod theme, the guitar’s pickups are hidden underneath a louvered pickguard!

This holistic approach to guitar building is a large part of what makes a Custom Shop guitar so special. It also helps explain why the Custom Shop has been so successful over the last 12 years.

The Master Builders

While many different kinds of guitars are built in the Dream Factory – including a full line of Custom Shop “production guitars” – the heart and soul of the Custom Shop concept is the Master Builder Program.

The Master Builder Program not only involves recruiting first-rate guitar builders and inviting them to contribute their unique skills to the co-op environment, but, more importantly, it provides Custom Shop patrons the opportunity to speak directly with the builder, ensuring that the guitar the customer receives is the instrument he or she wanted.

“Look,” says John Grunder, the Shop’s head of sales, “when a customer opens the case of a Custom Shop guitar he’s waited a year and paid his hard-earned money for, we want his expectations to be exceeded.”

The Master Builder Program’s focus on communication and teamwork ensures the highest level of customer satisfaction. “It really makes the difference,” adds Page, “between just being guitar builders and actually being a team with the customer.”

Two Types of Guitars

Custom “one-off” orders run the gamut from high-dollar works of art (last year’s Catalina Island Blues Festival commemorative Stratocaster was auctioned off for $50,000) to slightly modified versions of standard production models. Within that range, there are “set necks,” semi-hollow bodies, exotic finishes, special woods, custom hardware set-ups, you name it.

“Basically,” says Grunder, “we make two types of guitars – player guitars and art guitars. There are a lot of people who buy guitars because they want to put them on the wall. They want something really unique, and they’re not necessarily going to take it out and play it in a club. And then we do a lot of guitars for players who just want a really unique or personalized guitar that they can take out and play.”

These personalized guitars can require any number of modifications to make them fit the desires of their future owners. These deviations from the norm can include major construction changes, from woods used to hollow chambers being carved into the body to reduce weight.

In one case, a client requested the installation of LEDs in the fingerboard underneath carved-pearl stars to facilitate late-night visibility. Whether this was to make it easier for the player to see where he was on the neck, or just to make it easier for the audience to see him, remains a mystery!

Soon, macro programs will be written for the VF-4 for cutting intricate fretboard patterns, which will allow this type of ornate inlay work to be accomplished in a fraction of the time it now takes to do by hand.

Guitars as Collectable Art

The art/show guitars the Custom Shop has created have been some of the most dazzling musical instruments ever made. One needs only to flip through the Fender Custom Shop Guitar Gallery, published by Fender and Hal Leonard, to get a taste of the beauty and variety of which the Custom Shop is capable. From the Harley-Davidson Stratocaster, with its etched-aluminum body and gold hardware, to the one-of-a-kind “Disney 75th Anniversary Hand-Carved Stratocaster” by staff artisan George Amicay, the possibilities seem endless.

But, no matter how breath-taking these art guitars are, for the guys in the Custom Shop – all players themselves – it’s the player guitars that really excite them.

“Art guitars are real guitars – they play and sound great – but they’re still art guitars,” says Page. “From the guitar player side of it, the most exciting thing for me is when a customer who is not a famous musician – you know, just a regular guy – sends a letter that says, ‘I just got the 1959 Strat I ordered, and it’s the most amazing thing I’ve ever played. It brought tears to my eyes.’ And we get letters like that all the time, from players who got the guitar of their dreams.”

The Future of the Custom Shop

Over the years, the Custom Shop has exceeded all expectations, and as an added benefit, the Shop has positively affected regular production.

“By keeping its ‘finger on the pulse’ of the needs of players, the Custom Shop has been able to stay on top of trends,” says Boulanger, “and the knowledge the Shop has gained from interacting with musicians has trickled down into regular Fender production in many ways, improving the quality and variety of the Fender guitar line.”

A lot of what gets passed on to the regular production lines are subtle details like peghead shapes, fret sizes, certain finishes and hardware specs. The wide choice of guitars now available from the regular production factory has freed the Custom Shop to focus a little more on its mission. Where Custom Shop builders had previously been bogged down in large batch orders of specific models, the regular production factory now is taking over some of this load, leaving the Custom Shop craftsmen more time to recenter their efforts on projects more demanding of their specialized skills.

With the current backlog of custom-order guitars, Boulanger says the ability of a CNC to save time will be appreciated. “The speed and accuracy of the Haas enables a much faster turnaround time for product; and the dependability, coupled with excellent and timely service, means an extremely low amount of down time. Once again, the Haas VF-4 has cut our cycle time by 75% – it was the perfect choice.”

With the Haas, we have cut our tolerances in half while increasing our output by 400%. The stoutness of the VF-4 and the 10K spindle have allowed us to increase our feed rate from 25-30 inches per minute to 150-200 inches per minute.

Steve Boulanger, Head of Fender Custom Shop Engineering and Tooling