Mastering the Art of Smooth Cruise

Leonardo da Vinci, the original “Renaissance Man,” is best known for his paintings – most notably, the Mona Lisa and The Last Supper – and for his anatomical sketches, such as the Vitruvian Man. Often overlooked, however, is da Vinci’s renown as a scientist, engineer and inventor.

Throughout his life, da Vinci immersed himself in scientific studies – from aeronautics and anatomy to mechanics and physics. Recording his observations almost daily, da Vinci documented his ideas, discoveries and inventions in a series of journals, sketching concepts for such things as a rotor-powered helicopter, an articulated wing, a lens-grinding machine and a device for testing the tensile strength of wire.

A master of mechanical principles, da Vinci utilized the concepts of leverage, momentum, centripetal force, cantilevers and gears in his machines. His ideas, however, often were vastly ahead of his time – or impossible to realize, given the technology of the day.

Such was Leonardo da Vinci’s concept for a stepless, continuously variable transmission (CVT), which he sketched in the 1490s.

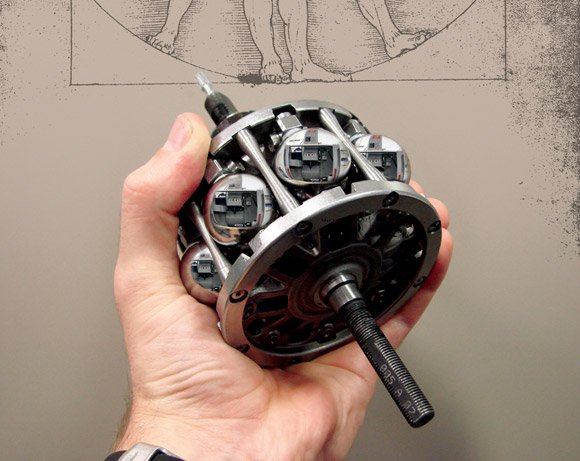

A CVT allows the ratio of the rotational speeds of two shafts – such as the input shaft and output shaft of a vehicle or other machine – to be varied continuously within a given range, providing an infinite number of possible ratios. The typical mechanical transmission, on the other hand, provides only a few discrete gear ratios.

It wasn’t until the 1930s – more than 450 years after da Vinci conceptualized the idea – that the first real-world models of CVTs for automobiles were produced. Unfortunately, a variety of problems – cost, scalability, efficiency, weight – has kept CVTs from widespread adoption, and limited their practical applications.

500 Years Later, Another Renaissance Man

In the late 1990s, cycling enthusiast Donald Miller, a former real estate developer-cum-inventor, became interested in building the world’s fastest bicycle. Analyzing the challenges involved, he quickly found that the transmission was a limiting factor. While looking for new ideas, Miller came across the concept of a CVT. His subsequent experiments led him to develop a continuously variable planetary (CVP) transmission – a revolutionary new CVT technology based on spheres, rather than gears.

In 1998, Miller and a group of investors formed Motion Systems, Inc. (MSI) to develop the technology. By 2000, he had developed a concept with the potential to address all the traditional weaknesses of existing CVTs, and applied for the first patents covering the technology.

Tests on the transmission by an independent testing laboratory quickly verified the potential of the revolutionary technology, and revealed applications far beyond just bicycles – to virtually any device that has a transmission. Rob Smithson, a transmission expert involved with the testing laboratory’s preliminary assessment, was so impressed with what he saw that he subsequently joined the company, first as a consultant, and later as Vice President of Product Development.

Smithson’s goal was to build a world-class engineering team that would develop the still-raw technology into a successful commercial product. Fallbrook Technologies, Inc., was formed to do so, with headquarters in San Diego, and research and development taking place in Cedar Park, Texas. Miller became Fallbrook’s Vice President of Advanced Research, and the company immediately began an aggressive research and development effort. In honor of its 500-year-old predecessor, the new technology was named the NuVinci™ CVP.

Concept to Reality

Keeping with Miller’s initial inspiration, the first commercial application of the NuVinci CVP was for bicycles. The bike CVP would undergo an accelerated development program, while additional parallel projects were started. The ability to make modifications to parts in a timely manner would prove crucial to keeping the momentum going during development. Concurrently, next-generation prototypes would be needed to support product and business development.

At the time, Fallbrook was renting less than 2000 square feet of office, test, assembly and shop space. When considering the equipment they would need for R&D support and prototyping, the space limitation quickly reared its head as a problem. With the project underway to develop the bike CVP and bring the product to market, time was of the essence. There wasn’t time move into a larger facility, so both the machines they purchased and the machinists running them would need to be very versatile. Fallbrook committed to developing its own machining capability in early summer of 2004.

“We knew we were going to need machining capability,” Smithson says, “but we were not sure which equipment best suited our needs. The design was going to change as the technology rapidly evolved, and we only had a basic idea of what the final part requirements would be. We understood that we had to control our own destiny, and the fast turnaround we’d need on prototype parts could only be possible with our own prototype machine shop.”

Among the many people Smithson contacted for advice was Eric Foster at Haas Factory Outlet – Austin. Foster introduced Smithson to Mark House, an experienced and creative machinist who had been around virtually every machine tool made, and had substantial experience starting up a new shop – from selecting the equipment and people, to running the entire operation. The son of a master machinist, Smithson hit it off immediately with House, and they found a lot of common ground.

Only months into the adventure, Fallbrook acquired more space at the existing facility and finalized plans to add a machine shop and personnel. Mark House joined Fallbrook in June 2004 as Prototype Shop Supervisor, tasked with developing a shop that provided machining capability, as well as areas for assembly, testing and development.

“When I first met with Rob [Smithson] and David Markley, Fallbrook’s Director of Engineering, it was just to give them my opinion on the types of equipment necessary to make the Fallbrook parts. There were no prints to evaluate, only a desktop demonstration unit and a sealed hub in a bicycle. Some of the parts initially looked like they had complex contours, which would be rather difficult to machine on manual equipment. In addition, some parts needed excellent surface finishes, and others required working with hardened bearing steel. CNC capability was a must,” House recalls.

Although initial quantities of R&D prototypes would be small, they were sure to increase, followed by higher quantities of pre-production prototypes. To handle the machining, Fallbrook ordered a Haas VF-2 VMC with a 4th-axis rotary, and a TL-2 Toolroom Lathe. As plans for the machine shop came to together, the engineers continued designing – solving the complex problems common to any new technology – and the business-development team continued building strategic relationships.

Work continued on the bike CVP, and after completing a design for a new hub, Fallbrook started looking for ways to introduce their technology to the public. They chose the 2004 Interbike show in Las Vegas – the largest bicycle trade event in North America – to debut the NuVinci CVP.

Because the new Haas equipment was not yet in place, the majority of machined components had to be sub-contracted – with a deadline allowing the Fallbrook team only one month to complete assembly and validation tests of the demonstration units. Unfortunately, the sub-contractor failed to deliver the parts as promised, raising concerns as the deadline approached. Unable to wait any longer, the Fallbrook team pressured the vendor for answers, only to find out that not a single part would be ready on time. “You just can’t imagine how badly we were burned by this vendor,” says House. “All of our efforts to this point had been placed in jeopardy. You can’t reveal your technology to the world with an empty booth.”

Midway through the effort, Fallbrook’s VF-2 became operational, and the TL-2 was being set up. Unable to find anyone to commit to making parts on such short notice, and with the deadline fast approaching, Fallbrook’s only option was to do the work themselves. They only had four weeks to produce, assemble and test parts that were originally allocated more than three months to complete.

“We were out of options,” says Product Development Engineer Loren McDaniel, who helped House ready the prototypes for the show. “Having had manual machining experience in college, I had to quickly familiarize myself with the TL-2, so that I could begin cutting metal. With little CNC programming and operating experience under my belt, I was a little apprehensive to jump into CNC machining on these critical parts. But the TL-2 was so intuitive and easy that I was producing parts in no time. The machine gave me the hand-operated controls I was comfortable with for setting up the tool, but really proved its worth when I hit the ‘go’ button. It was cutting complex contours and threads that I had drawn in CAD only days before. As a product development engineer,” McDaniel continues, “there is a lot to learn when it comes time to actually make the parts I design. The TL-2’s Intuitive Programming System (IPS) and ease of operation allowed me to make parts confidently.” With the new mill and lathe on the floor, the team was able to produce parts in less time than originally believed achievable.

Fallbrook arranged transport to Las Vegas, and the final parts were ready the day prior to departure. Once the staff reached Interbike, they completed the assembly in the hotel room. Luckily, the hub assembly went together without a hitch, but the team had to forgo the planned testing and tuning. Even with the nail-biting, down-to-the-wire experience leading up to the Interbike trade show, the great design and newly finished prototype parts allowed Fallbrook to successfully unveil the NuVinci technology to its first market, and take the first step toward commercialisation.

Fallbrook (and partners) have since returned to Interbike with new and improved mass-production hub designs. Production bikes incorporating the advanced-technology NuVinci hubs were first made available at the 2006 Interbike show through Ellsworth, a prestigious bike company known for their innovative designs. Batavus BV, the Netherlands’ premier bicycle company, had production bikes using the NuVinci transmission available in early 2007. Since their introduction, both the bikes and the NuVinci transmission have garnered numerous prestigious awards.

Fallbrook continues to move forward with licensing agreements for new applications of the NuVinci transmission, including light electric vehicles (LEVs), outdoor power equipment and automobiles. “The biggest challenge,” says David Markley, “has been that the applications are endless. We’ve had to focus our energy and resources to ensure a successful commercial launch, but many companies want to see our technology in their product lines. The NuVinci technology literally sells itself. In fact, I often laugh, because the questions we receive from potential partners quickly change from technical details to ‘Where can I buy one?’ as soon as they’ve ridden one of our bikes.”

New Challenges

Fallbrook now holds more than 150 patents and patents pending worldwide on the CVP technology, with many more patent applications on the way. Every day brings a new challenge to the company’s growing prototype machine shop, as new applications demand new prototypes. Meanwhile, continued advancement of the CVP technology by the engineering staff brings its own set of challenges.

The company’s machine shop now encompasses 3300 square feet within an 18,000- square-foot facility. With the addition of a Haas SL-10 lathe, high-speed VF-2 VMC and, most recently, an SL-30 lathe with high-torque 2-speed gearbox, the prototype shop has even more machine capability. Despite the additional equipment, however, House says that most of their final hard-turning operations are performed on the TL-2. “The versatility and ease of use make that machine the favorite in the shop,” he says.

“Our in-house manufacturing system allows us to control our own destiny,” House continues. “Having to depend on outside vendors, even if our project milestones were met, wouldn’t give us the knowledge we gain by manufacturing the parts ourselves. We have a strong core team, and machines that allow us to meet the company needs. Being a start-up company, we still ‘make do’ with less equipment than a well-established machine shop would have. But the creativity of our group, and the versatility of the Haas machines, leave very little need for us to outsource anything.” Fallbrook is growing rapidly, and the machining requirements are changing constantly. Prototypes consist of many parts that are made from high-purity hardened alloy steel. Tolerance-stacking issues must be minimized throughout the design, due to the relatively confined space and the number of precise fits – characteristics shared by both conventional geared planetary transmissions and the NuVinci variable planetary. Designs targeted for near-net- shape production processes increase the complexity of prototype parts, as well. For example, a cast part will have draft angles, and such parts usually require 3-D surface milling. Future designs will likely utilize a greater variety of super alloys, castings, powdered metals and high-tech composites.

There have been plenty of challenges to date, especially working with extremely hard steels. Rather than grind hardened parts, the Fallbrook team performs the much-preferred hard-milling and hard-turning processes on the Haas equipment. The machinists have developed proven processes for roughing, heat-treating and finish-machining steels that can be as hard as RC 67, and they easily achieve the desired surface finishes and maintain the required tight tolerances.

Due to the intense development environment of Fallbrook, working closely with the engineering department is a way of life. Though many of Fallbrook’s engineers have some experience with manual machine tools, the machine shop is often consulted during the design process to ensure that parts are producible. Upon completion, parts are hand-delivered to the design engineers for review, at which point additional assistance may be required: There may be modifications, questions dealing with processes or a they may need assistance during assembly. This relationship benefits all team members. The designers receive immediate feedback on their parts, and improvements or processes can be discussed “real-time.” Even though manufacturing methods will change for large-scale production volumes, discussions early in the product-development process can add significant value down the road.

“It’s very satisfying to see the parts you’ve made for conceptual designs get assembled and tested, and then see the end product in production,” says Clayton Phillips, Engineering Technician/Machinist. “Working with the engineers, exchanging feedback and running tests is very rewarding. Try to get all of those positive benefits through a sub-contract relationship!”

The number of prototype designs Fallbrook is producing continues to increase, so having machine tools from one supplier increases the machine shop’s efficiency. All of Fallbrook’s CNC equipment is from Haas, which saves time and eliminates confusion. Training is minimized, and machinists have the freedom to run multiple machines. “Not having to deal with multiple controls and systems adds to the pleasure of working in this shop,” says House.

“The reliability and repeatability of the equipment has really come through for us,” House adds. The machine shop has a superior “uptime record,” which minimizes problems and provides the necessary environment to concentrate on delivering accurate prototype parts in a timely manner.

“Having a high-tech yet simple-to-use machine like Haas on-site is a big benefit to our Engineering Development Department,” explains Hieu Do, Engineering Technician/Machinist. “It raises our confidence for on-time delivery, and also allows us to quickly resolve issues on designs or test improvements for future products.”

Prototyping Fallbrook’s innovative NuVinci CVP product designs continues to lead to new revenue streams for the company. As engineering is being completed for an ever-expanding range of new applications, the machine shop will continue to prototype the future; changing the way the world transfers torque.