Black Gold

With the price of a barrel of oil at an all time high, and in order to meet burgeoning global demand, the world’s big oil companies are embarking on major new programmes of exploration.

New wells are being bored, new pipelines laid, new rigs constructed, and new extraction and refinery equipment is being designed and manufactured. Compared to other industry sectors, the projects and their capital expenditure are frequently vast, and can mean lucrative contracts for product and component manufacturers with the necessary technical capability and experience.

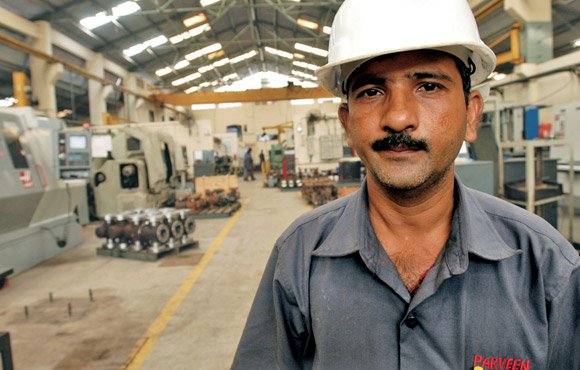

The origins of Parveen Oilfield can be traced back to the year 1960, when the family business was founded to manufacture metallic conduits for electric cables. In 1983, the company diversified to meet increasing demand from the Indian oil industry. In the two decades since, it has grown to be a leader in the design, development and manufacture of oilfield equipment. Its name is synonymous with quality and high-precision machining, and as a one-stop shop for its global customer base. Works Director Mr. N. H. Jeswani has been with the company from the early days.

“Not long after our first few contracts with companies in the oil and gas sector, we started designing and manufacturing products ourselves,” Jeswani says. “We began by producing basic wire-line service tools and pipe fittings for the oil industry in India, before gradually increasing our product portfolio for the export market.”

Today, Parveen Oilfield has its headquarters – with 110 employees – near Mumbai, another smaller facility in the older part of Mumbai, plus a further two facilities in Delhi, where a third is shortly to be constructed. Across all facilities Parveen employs around 500 people, who help the company meet demanding delivery schedules for its range of around 300 different products.

The Parveen portfolio includes the design and manufacture of a wide range of equipment – for cementing, coil-tubing pressure control, gas lifts, rotary drilling, sub-surface flow control, sucker rods, well heads, Christmas trees, “fishing” and logging tools, and valves. In fact, the company does almost anything and everything needed above and below the surface during all phases of oil and gas exploration.

The Technology Leap

About three years ago, the company decided the time had come to replace some of its older Indian-manufactured machine tools with CNC technology. Mr. Jeswani had seen Haas machines at an exhibition in Mumbai, where the Pune-based Haas Factory Outlet, a division of Omira Marketing Pvt Ltd, had a stand.

“Cost and quality were the primary reasons why we opted to purchase a Haas SL-30 big-bore CNC turning centre,” he says. “Of course, so many oilfield products and components are tubular that it made sense to start with a turning machine.”

Such was the success of the Haas SL-30 that Parveen recently added to its Haas armoury, purchasing a further four machines in 2005: another SL-30, an EC-1600 horizontal machining centre, a VF-5 50-taper vertical machining centre fitted with a Haas HRT-450 rotary table, and an SL-40 turning centre with an SMW indexing chuck designed specifically to allow machining of all the faces of steel valves in a single setup.

“The Haas machines have proved very reliable,” explains Jeswani. “The company works around the clock, so reliability is a key factor. We have also experienced improved productivity and higher output rates since the machines were installed.”

Parveen operates 24 hours a day, seven days a week. Where in western companies this would represent a three-shift system, astonishingly, Parveen operates just two shifts, with employees working 72 hours a week across six, 12-hour shifts, with just one day off a week on a rotation basis. With labour already working at maximum capacity at Parveen, investment in CNC machine tool technology made perfect sense.

“Our biggest challenge is keeping up with demand. Once a customer has placed an order, it’s invariably required yesterday,” quips Mr. Jeswani. “We make everything to order rather than for stock, so now that we have reliable machines, meeting tight delivery schedules is far easier.”

With business swift, Parveen’s Rabale site is at near capacity. An expansion representing an increase in floor space of 50 percent is currently being commissioned. It will house the latest CNC machining equipment, including a total of 13 new Haas machine tools, which are presently on order. The company’s order book is so healthy that Mr. Jeswani is confident he can keep the new machines and extra staff just as busy.

Low labour costs have certainly helped Parveen, as has the relative abundance of young, highly skilled engineering graduates passing through India’s university system. But it’s also the company’s willingness to invest in technology and quality processes that enables it to win and retain customers in the long term.

Parveen has embraced CNC technology and is reaping the rewards. The company has also achieved ISO9001:2000 quality accreditation status, and holds 13 API (American Petroleum Institute) licences to manufacture oil industry products, which it claims is the most held by any company in India. Add all this to its 25 years of experience in the oil sector, and it’s easy to see why Parveen’s services are so popular.

Around 70 percent of the company’s production is exported, sold via Parveen’s extensive network of agents. As an oilfield supplier, it should come as no surprise to learn that the company’s chief export regions are the U.S., Canada and the Middle East.

“Our customers are interested in quality, delivery and trust,” says Jeswani. “We have an ISO audit every six months, and an API audit every two years. Price is less of an issue, given the high cost of oil, a factor that is driving the entire sector, making it very buoyant and providing most suppliers with a profitable period,” he concludes.

The company works around the clock, so reliability is a key factor. We have also experienced improved productivity and higher output rates since the machines were installed.

Mr. N. H. Jeswani, Works Director