T&T Precision

T & T Precision was established in 1996 with the aim of supplying the local industries with high quality tailored engineering and tooling solutions. Since then they have built a successful reputation of delivering trust, reliability, flexibility and quality as standard.

Brothers Victor and Finbarr Twohig were toolmakers by trade. They trained in electronics but noticed that much of this work was going abroad, while the growing industry in Cork was in medical devices. With the help of some grants and while still holding down their day jobs, they opened a 4,000 sq ft factory and began designing and making their own medical equipment.

They have expanded organically over the last 22 years, hand-picking both new markets and a skilled workforce as they grew. By investing in their team of 40 including highly skilled design, application and manufacturing engineers, they are showing consistent growth year upon year.

T&T Precision’s design department are now creating workholding solutions and robot clamping for some of the largest medical device and aerospace companies in the world, including Johnson & Johnson, Stryker Orthopaedics and Saffron Aerospace. Designers work closely with the precision engineers to deliver strong design for manufacture solutions, seeing each concept through to completion using leading edge CNC machines.

After several expansions, the original factory had been outgrown. In 2015 T & T Precision moved to a state-of-the-art design and manufacturing facility on the outskirts of Cork, totalling 32,000 sq ft. They were already running a Haas lathe and wanted to invest in mills as well.

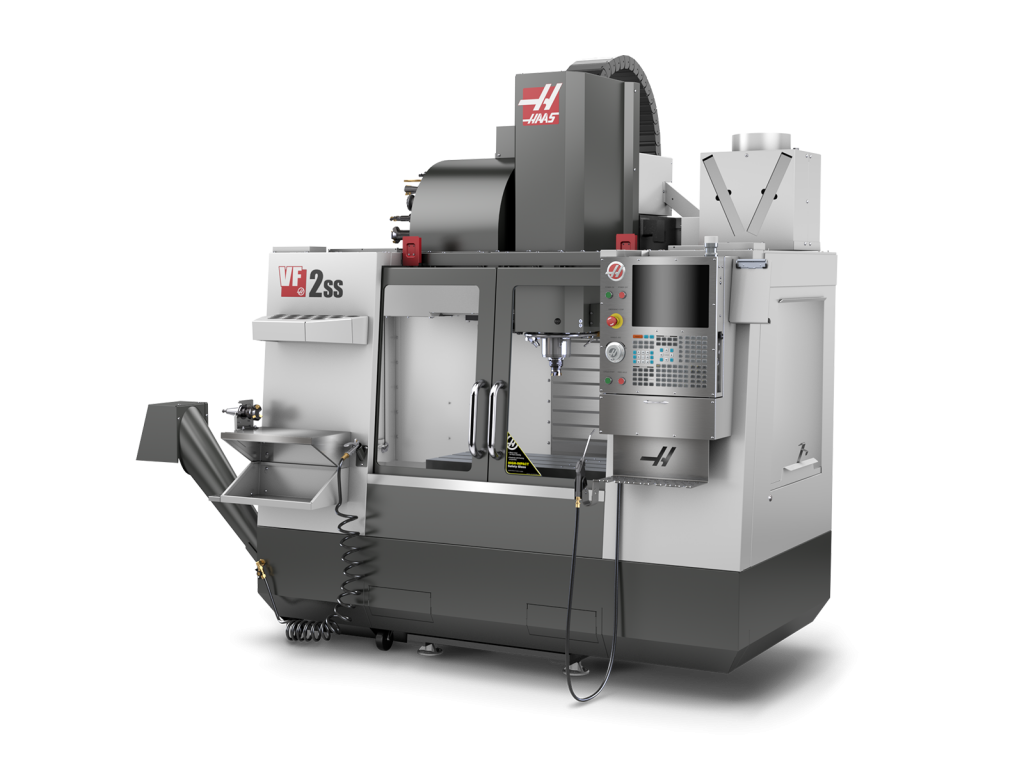

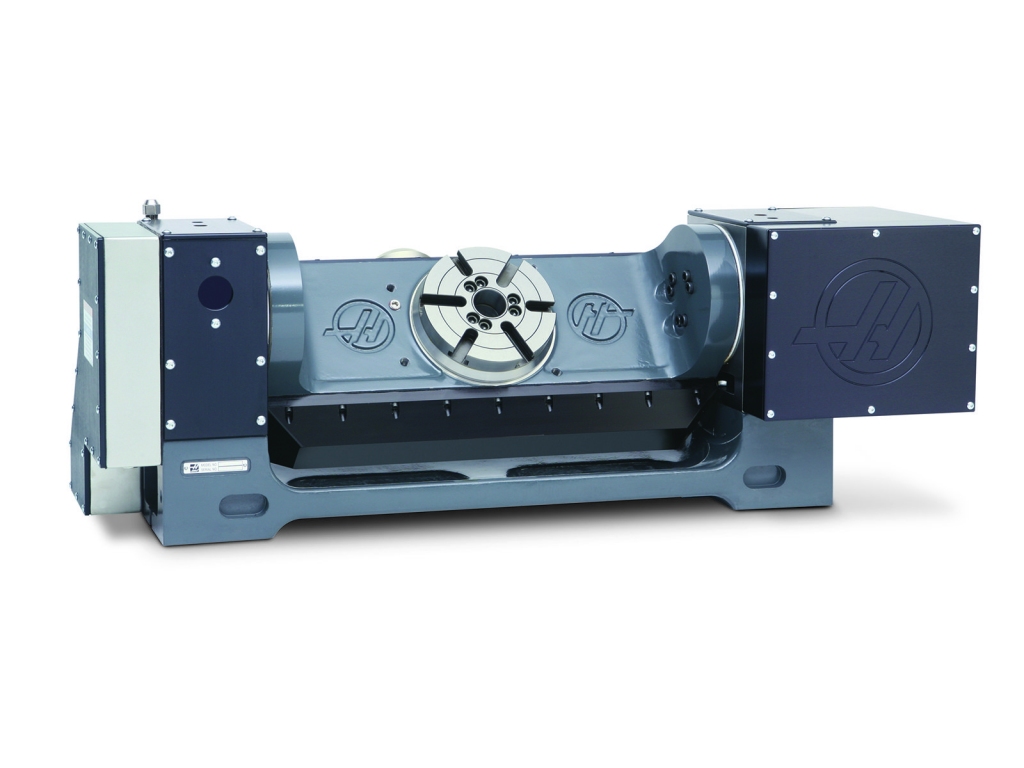

“We knew Haas were very efficient, cost effective and reliable machines,” says Victor. “We chose a VF-2SS vertical machine with a 5-axis trunnion. It’s a fast machine, our cycle times improved by 15% straight away.”

“We found the transition to 5-axis machining easy and the gains have been huge in both reduction of man power and increase in quality. The purchase coincided with an increase in our workload; the machine simply powered through the orders.”

T & T Precision have since added to their set-up with a VF-5SS and eight UMC-750 Universal Machining Centres, partly funded by government grants which are directly related to the number of people the company employs.

“The UMCs have a smaller footprint than some of our machines but with a larger workspace. It gives us more freedom to machine components of greater dimensions.”

The UMCs have a fully simultaneous 5-axis with T & T Precision opting to add 12,000-rpm spindle, Through Spindle Coolant, and High Speed Machining for greater speed and accuracy.

“We can now machine complex shapes in a single setup which has hugely reduced our labour times. Tolerances are improved and datums are in sync, which means the quality of the finished part is greater, even on hardened tool-steel and titanium.”

With this level of investment, coupled with their commitment to innovation, Victor is predicting that the company’s turnover will double to seven million by 2020. “We’re recruiting more design engineers to manage the demand for our services,” explains Victor.

“We have a great relationship with Haas; their training and customer service have been excellent. We will be working with Haas for many years to come.”

“We knew Haas were very efficient, cost effective and reliable machines. We chose a VF-2SS vertical machine with a 5-axis trunnion. It’s a fast machine, our cycle times improved by 15% straight away.”

Victor Twohig

“We can now machine complex shapes in a single setup which has hugely reduced our labour times. Tolerances are improved and datums are in sync, which means the quality of the finished part is greater, even on hardened tool-steel and titanium.”

Victor Twohig