BOOSTING THE FLOW OF INNOVATION WITH 5-AXIS MACHINING.

Wandfluh UK has been customizing bespoke hydraulic valves and electronic control systems for more than 30 years. Manufacturing of the original product takes place at the family-owned Swiss head office before shipping across the world to be adapted by sub-contractors to individual customer requirements. In 2020, Wandfluh UK’s Managing Director, Trevor Allen decided to add an in-house machining facility, giving greater control of supply and quality of their ever increasingly complex machined products. With the construction of a purpose-built CNC workshop extension, bringing Wandfluh’ s Warwickshire site to over 1,800m2, the UK manufacturing department was born.

The team began exploring the options for CNC machines to equip their new workshop. Once they had spoken to Haas, they knew they had found the right supplier. Engineering Manager Steve O’Sullivan explains, “The level of support Haas gave us made it easy to choose. They helped us figure out exactly what we needed and what we would be capable of. I cannot praise our Haas sales manager, Ryan Smith, enough; he not only exceeded expectations during the selling process but continues to do so. Whenever we have any questions or concerns, we simply give him a call, and he’s always eager to assist. It’s a real confidence boost knowing he’s there to help.”

“Our first two machines were ordered, UMC-750 Universal Machining Centres, equipped with simultaneous 5-axis machining, a 12,000 rpm spindle, and a 40+1 side mount tool capacity,” says Steve. “Then, we began searching for machinists. We chose programmers who already had experience in 5-axis machining, and Haas customized the training to match their existing knowledge, ensuring that we made the most of our time with the experts.”

Wandfluh UK specializes in lower-volume, specific projects, primarily serving the subsea and military industries. While valves are still made in Switzerland, the one-off bespoke products are now manufactured within the UK factory. Customers place repeat orders again and again, because they appreciate the combination of Swiss quality and superior bespoke UK design.

“With the addition of our Haas machines, we can machine complex work in-house. This allows for our designs to be more and more complex, reducing size and weight whilst also improving hydraulic performance and efficiency. We can design, build, and test to each customer’s particular needs.

“By choosing the 5-axis machines we have experienced improved precision and can manage greater complexity with fewer setup requirements. Our subsea parts in particular can be very complex; the Haas UMCs are ideal for the job. The accuracy of Haas machines allows us to meet all of the fine tolerancing requirements for hydraulic systems.”

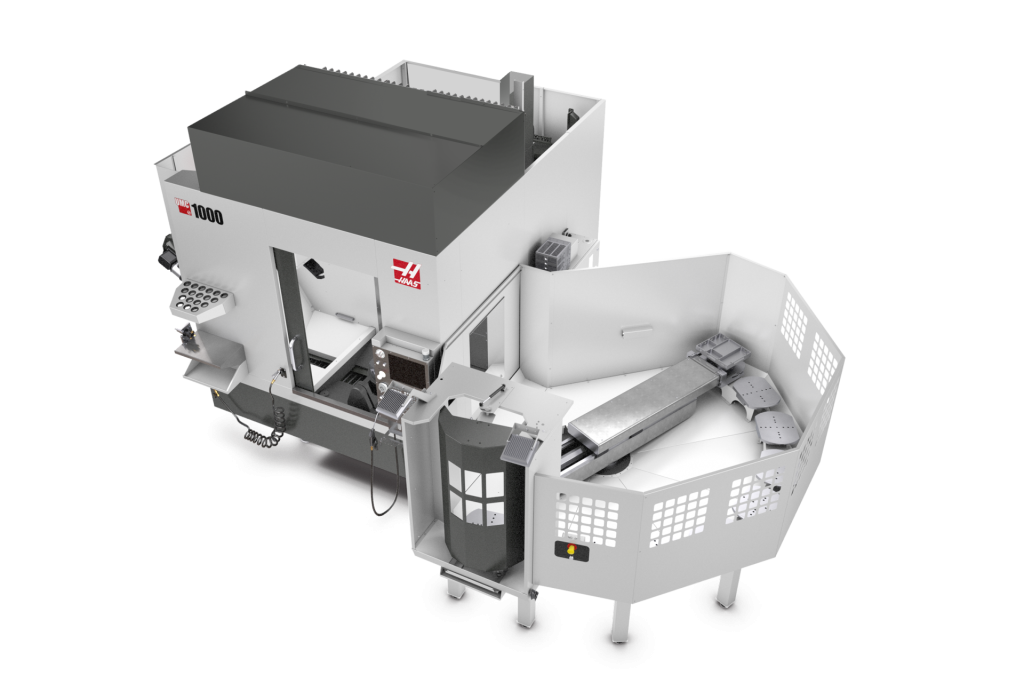

Wandfluh UK has since added a third UMC-750 to the workshop, this time with a 50-tool capacity to aid flexibility of parts, reducing additional set-ups on complex, multitool machining. This was coupled with their largest investment to date; the UMC-1250, partnered with a fully integrated six station pallet pool. This king of a machine in the workshop, boasts a 70+1 station side mount tool changer along with a generous 1,270 x 762 x 711 mm envelope, increasing operational volume even further.

“The pallet pool is a game changer. We operate a single shift, but we run the machine 24 hours. We can fit in our largest products, giving us greater scope during both the design and machining process and, because 5-axis machining is not operator heavy, complete them in just two operations.

“The Haas machine control system offers a substantial advantage by ensuring seamless transitions for our programmers as they switch between various machines,” concludes Steve. “Moving forward, our commitment remains unchanged – we exclusively rely on Haas.”

With the addition of our Haas machines, we can machine complex work in-house. This allows for our designs to be more and more complex, reducing size and weight whilst also improving hydraulic performance and efficiency. We can design, build, and test to each customer’s particular needs.

Steve O’Sullivan Engineering Manager