BREAD! Dowson Food Machinery

Dowson Food Machinery was established in Yorkshire in 1982 under the skilled entrepreneurship of founder John Murgatroyd. John began work as an engineer for Rolls Royce before joining Hugh Steepler in Leeds, where he was tasked with manufacturing comb plates and slicer frames for the bakery industry.

He set about designing new products for slicing and bagging bread, and before long was supplying bespoke equipment and service support to many of the UK’s leading bakery groups, as well as to smaller independent and artisan bakers.

Dowson had established a reputation for providing quality British engineering solutions to some complex bakery challenges; their machines becoming the leading standard for the industry with their engineering excellence and renowned reliability.

Now run by Managing Director Nick Lacey, the company exports across the five continents and has machines installed at many of the UK’s leading bakery groups such as Warburtons and Hovis.

The success of the business meant that expansion was inevitable and in 2015 they moved to a new 48,000 sq ft facility in Bradford, nearly three times the size of the original factory.

Now employing 60 people and with the space for more equipment, new lines were designed to include products for speciality breads, flatbreads, rolls and tortillas.

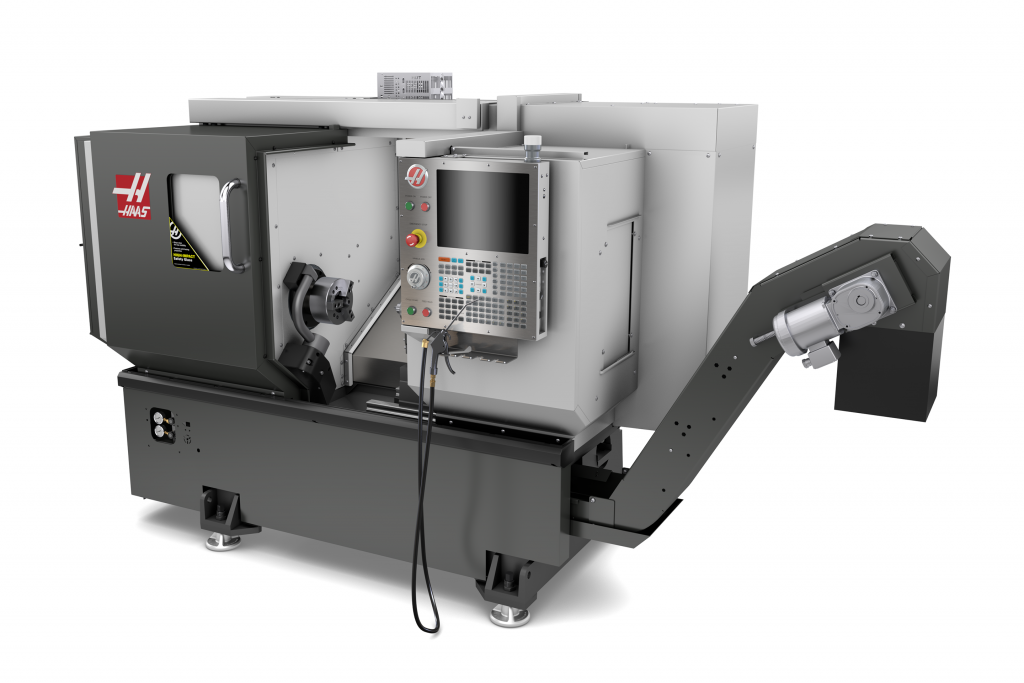

Their main asset today, is in-house CNC machining capability. “We offer more than our competitors,” explains James Carson, Sales and Marketing Manager. “To have our own Haas machines on-site is not only economical, it gives us a level of control over quality and lead-time which we would never have by out-sourcing.

We can alter or modify a component to change the way a piece of equipment works, then test it straight away in-house. 90% of components for our products are now manufactured at the Dowson factory.”

In 2017 Dowson decided to replace one of their lathes and, after careful research, invested in a Haas ST-15 Turning Centre with a 20 hp 4,000 rpm spindle and 210mm chuck. “You get a lot of bang for your buck,” says Andrew Sands, Purchasing Manager. We paid less for the ST-15 than we did for the lathe we bought ten years ago and it more than matches it for accuracy and reliability.

“We were also attracted by the compact footprint of the machine. And the control is so easy to use; it’s similar to Fanuc which we were already familiar with, so we could start cutting straight away. We then spaced out the two days of on-site training we had in the package, allowing us time to build up some questions.

Haas were very flexible which meant we were able to make the most of our time with the instructor.”

The ST-15 joins a complete production line of equipment including welding, fabrication, paint booth and food assembly area. Here the engineers carry out testing, usually with a ‘live’ product which the customer has sent over, ensuring that any issues can be fixed prior to on-site installation.

As many of the products are Dowson’s own bespoke designs they have the capability to offer solutions to their customers’ problems, with the technology at their fingertips.

So, would Dowson recommend Haas? “Certainly,” says Andrew. “The experience has been entirely positive; the service is great and the machine is everything we need. It does exactly what it says on the tin.”

“The experience has been entirely positive; the service is great and the machine is everything we need. It does exactly what it says on the tin.”

Andrew Sands