Mikana in Aerospace

Mikana Uses Haas CNC Technology and Soars into the Future

Beyond the Speed of Sound

When the Blue Angels streak through the sky demonstrating the aviation excellence of the U.S. Navy, they are piloting the most versatile aircraft in the nation’s front line of defense – the F/A-18 Hornet. It was called upon during Operation Desert Storm to fight opposing aircraft and destroy ground targets on the same combat mission.

The twin-engine fighter/attack aircraft, also used by the U.S. Marine Corps and eight allied nations, showcases the capabilities of modern manufacturing while setting new records in reliability, maintainability and mission performance. At the roots of its success are the combined efforts of not only large contractors like McDonnell Douglas, Boeing, Northrop Grumman Corporation, General Electric Co. and Hughes Aircraft Co., but also essential job shops like Mikana Manufacturing Company, Inc., located in San Dimas, California.

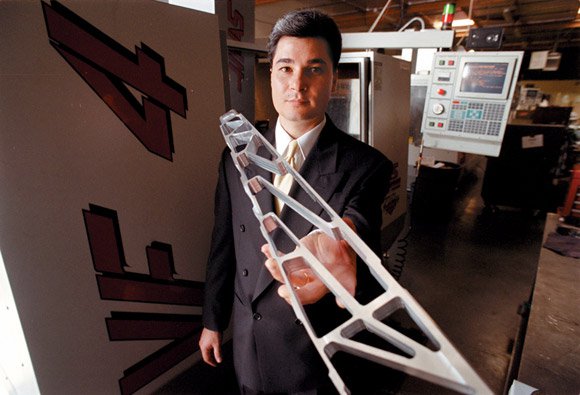

It is fitting that Mikana machines parts for the F/A-18, because the company and aircraft share many of the same traits. Both are on the cutting edge of technology and successfully pushing the limits to reach higher levels of achievement. “We are asked to do the impossible,” said Michael Allawos, president of Mikana, “which translates into providing precision parts on quick turnarounds. The way we achieve this is by being aggressive with our machines.”

Mikana’s philosophy has been working for them since opening their doors in 1985. They specialize in the aerospace and medical industries, using the latest manufacturing and business systems to remain competitive in the high-tech arena. As testament to their success in managing technology, during the recent glut in the aerospace sector, Mikana not only survived, but positioned themselves for growth.

“We have proven our abilities to our clients,” said Allawos, “and are being rewarded for our efforts with a backlog of projects extending into the next century. As a result we are expanding – buying new equipment – but not without control. Maintaining control of our growth enables us to continue doing the jobs we are best suited for, instead of having to do work that doesn’t fit our expertise.”

With Mikana’s growth came the purchase of their first Haas unit, a VF-4 vertical machining center (50″ x 20″ x 25″ travels) equipped with a chip conveyor and programmable coolant nozzle. “We’ve found that if you buy the best and most technically advanced equipment for your company,” Allawos said, “the people will rise to the occasion and perform miracles. That is why we thoroughly investigated our machining options before selecting Haas Automation for our shop.”

Richard Borowski, Mikana’s general manager, added, “We went to Westec and looked at the different manufacturers, then toured several facilities to see the machines in action. The more we saw of Haas, the more we were impressed.”

Allawos, a strong advocate of teamwork, has empowered Borowski to run the shop. “We were certain our volume could support several new machines,” Borowski continued, “but we remained cautious with our purchasing until we could put the VF-4 to the test. The machine started paying for itself the minute we flipped the switch on, and within a month it had proven itself to us.”

Allawos added, “We realized a 60% savings with the first machine, so we bought more.”

They had their second VF-4 VMC delivered within 6 months, and within a year and a half had two more Haas units running in the shop, both VF-2 VMCs (30″ x 16″ x 20″ travels). “There are three things a machine needs if it is going to make you money,” Borowski said, “versatility, repeatability and accuracy – crucial factors for maintaining good productivity. Our Haas machines come through in all categories.”

Productivity has skyrocketed. “We realized a 50% increase in productivity when we switched to the Haas VF-4 to manufacture the titanium fitting cover for the F/A-18,” said Borowski. “And at the same time,” he continued, “we were able to increase the life of the carbide inserts on the cutting tools twelve-fold.”

He attributes these accomplishments to the rigidity of the machines (provided by the heavy cast-iron base), the ability to run at higher rpm for longer periods of time, and the ability to maintain constant speed during bigger and deeper cuts.

These same characteristics are vital in machining the lateral cam Mikana produces for McDonnell Douglas’ MD-80 and MD-90 commercial aircraft. These parts are what Borowski calls “a titanium nightmare.” Starting with a 16-pound block of titanium measuring ¾” x 14″ x 16″, they use three setups to machine it down to a 3-pound finished part. “It’s a multi-angle type of cut, and we have to hold critical dimensions to five tenths [0.0005 inch],” Borowski said. “It’s a nightmare because of all the cutting and hog out. The titanium is tough and dense, and it requires more power to maintain the feed rate and keep up the rpm. The Haas machines have allowed us to more than double our output.”

Mikana has realized similar results in aluminum. A rib assembly part they manufacture for McDonnell Douglas starts as a 3600-pound plate of aluminum measuring 4′ x 12′ x 3″. The plate is cut into 300-pound blocks measuring 24″ x 30″ x 3″, which are then machined on the VF-2s into a pair of 15-pound parts. Keeping up with the production schedule means taking big cuts. “We really push our equipment, but never sacrifice accuracy,” Borowski said. “The rigidity of the Haas machines gives us the accuracy we need to maintain tolerances and meet quality control inspections.”

Mikana keeps a busy production schedule, completing 15 to 20 setups a week with runs of 1 to 30 parts each, so saving time in setup is crucial for staying on track. It begins with programming, where it is fascinating to note that Tom Anderson, one of their programmers, wrote posts for one of the first Haas units ever made, serial number 6006. The programmers use the latest CAD/CAM software to generate posts and incorporate a digital camera to create packages for the setup guys.

“Haas cut our setup time by over 30%,” said Borowski, “which is important to us, because some setups are 9 hours with 1-hour runs, while others are 3 days with 2-hour runs. Guys can do dry runs to check for tool paths and see the part being machined on the control panel screen without actually running the part. The control panel is very user friendly and our guys can get a lot of information right from the screen without having to go anywhere. They can make changes, proof the part, archive the program and run the job.”

Borowski continued, “We can run the same program over and over and not worry about whether it’s going to be close. The repeatability is always top notch and the Haas machines always do what you tell them to do.

“There are a lot of other things we like about the Haas units, for instance the way they come underneath the machine with the coolant instead of from behind. But the bottom line is we had a need for machines and Haas filled it admirably. And in doing so, helped us increase our delivery schedules, our relationships with our customers, and our ability to work in different situations.”

In accordance with their mission statement, Mikana set out to create a greater presence with their customers and influence the shape and direction of industry. They have made great strides in achieving their goals and have assembled the ideal combination of equipment, management and craftsmen to continue on their path of growth and financial stability.