Doran Precision Engineering

Kieran Doran installed his first manual lathe in 1993, in a small shed at the side of his house. His one employee, Leo McGreevey, began turning while Kieran was still holding down his day job, coming home and working on the new business at night.

Eager to follow in his fathers’ footsteps and having helped out during school holidays, Kieran’s eldest son Christopher joined the company in 2005 as an apprentice and in 2018 his sister, Ciara stepped into the Accounts Manager role.

Today, Doran Precision Engineering Ltd (DPE) specialise in the manufacture of precision components, offering batch production work, rapid response and rework services. Still a family run business, they employ 22 people, utilising 31 CNC machines.

90% of the factory’s output serves the aerospace industry, supplying to a worldwide customer base, making interior parts for aircraft giants such as Thompson Aero Seating and Collins Aerospace. They machine a wide range of Aerospace grade materials including aluminium, stainless steel and plastics.

All of their product is programmed by state-of-the-art software and are supplied with a full FAI. Doran was first accredited to ISO:9001 in 2006 and in 2018 were accredited to AS9100 Rev D.

“It was 2011 when we bought our first Haas. We wanted to offer machining on a larger scale, so looked for a mill with a more substantial capacity. We shopped around,” explains General Manager Christopher Doran.

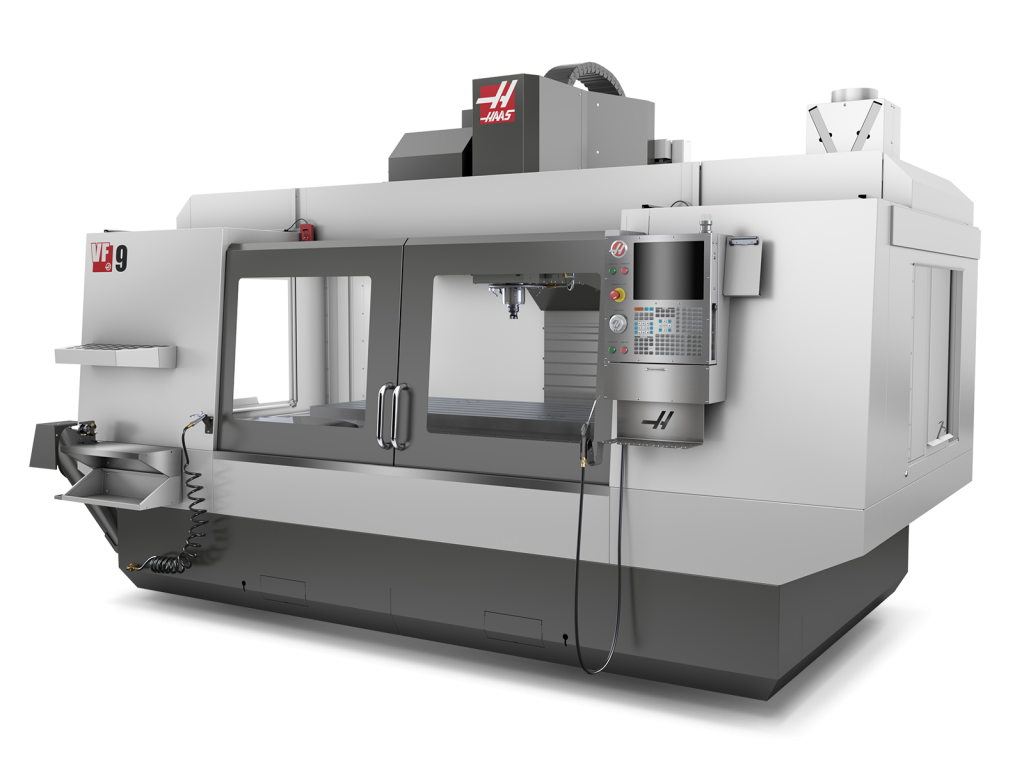

“Having been to the shows and looked at all the options, the one machine that stood out to us was the Haas VF-9. This machine had one metre of travel on the Y axis and for such a large frame mill, the price was exceptional.

“We bought our first Haas shortly after and haven’t looked back since.”

The VF-9 has used the whole of the 2,134 x 1,016 x 762mm table to machine everything from base plinths for aircraft seating to hinges for table assemblies, machining each with precision and power and never faulting due to size or weight.

Thus, began a strong partnership between Doran and Haas which has brought their total number of Haas machines to 16 in the last 8 years.

“The Haas control is similar to a Fanuc control so it mirrored our older machines. We were up and running straight away” explains Engineering Manager Kieran Poland.

“It meant we could use our existing programs which made the transition very easy. We only buy Haas now.”

Today, with three units stretching over 10,000ft² at their premises in Newcastle, Northern Ireland, capacity is rapidly increasing and the machines are in constant use.

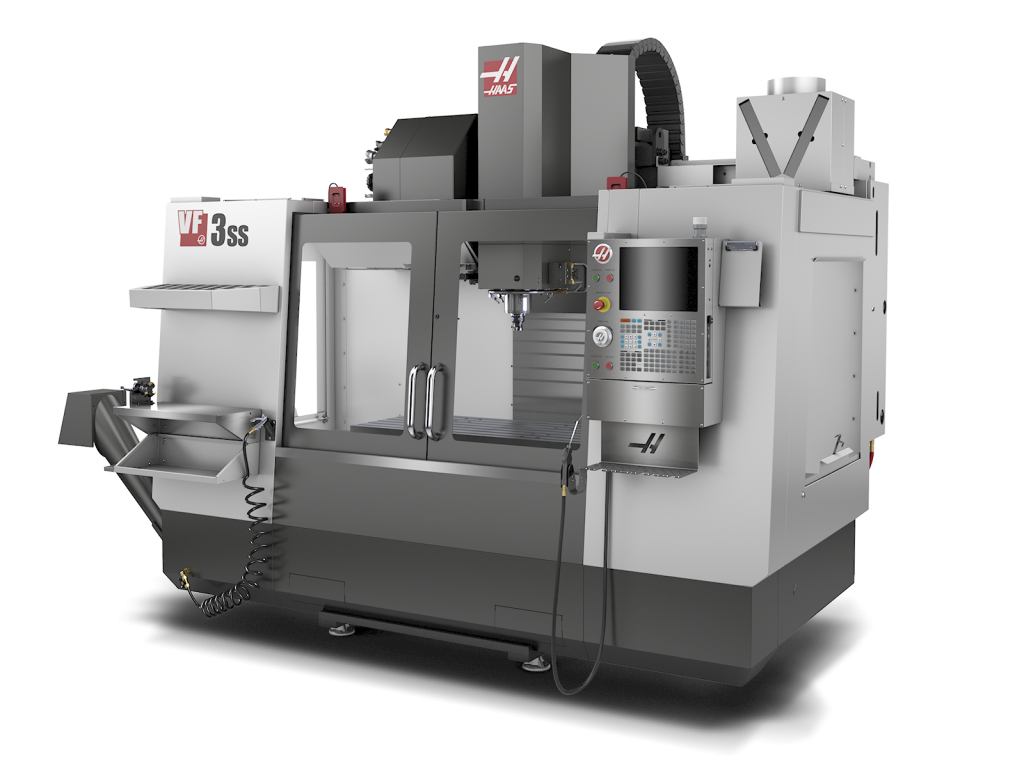

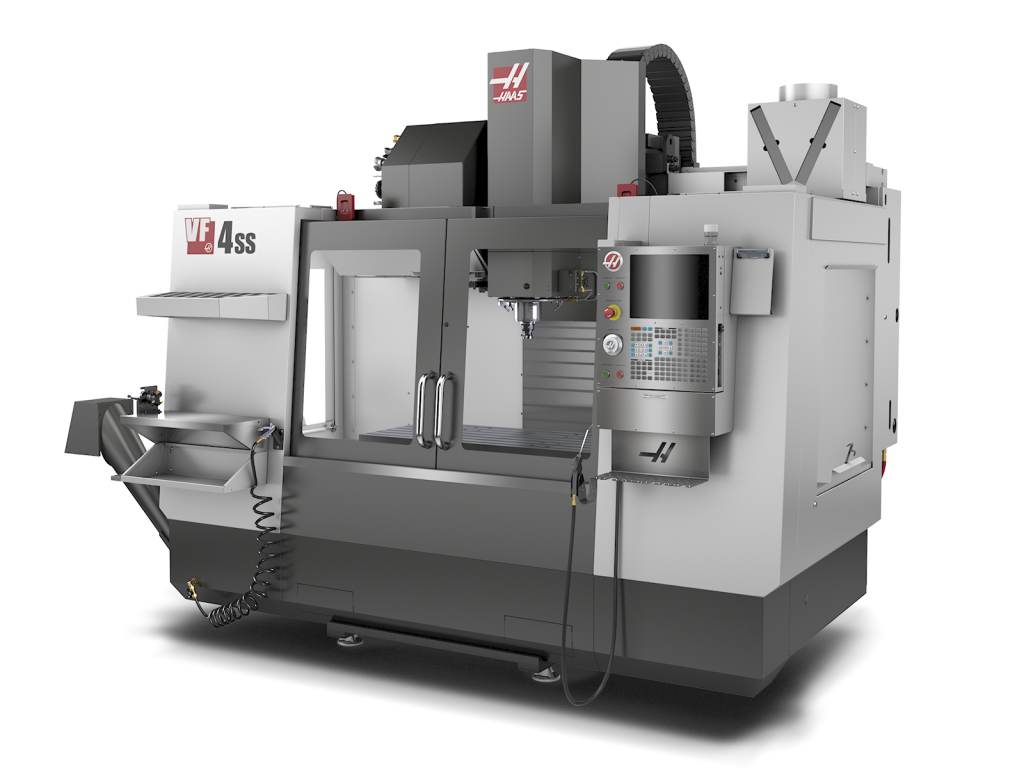

“We have 12 Haas Super Speed mills,” says Kieran. The Super Speed mills boast a 12,000 rpm spindle and high speed 24 + 1 side mount tool change.

“The Haas machines are invaluable. The increased spindle speed and rapids have reduced our cycle times by 50% and the spindle power is unrivalled. They cut aluminium constantly on full revs, as deep a cut as the spindle will allow. I haven’t found anything the spindle doesn’t have the power to cut.”

Christopher also values Haas’ reliable aftercare service. “We rarely have an issue but if we do need an engineer they’re on site quickly.

“We recently added three UMC-750 5-axis Universal Machines to our Haas family, allowing us to produce both small batches and prototype work in a much shorter time frame. Using the latest Mastercam package, with the UMC’s 12,000 rpm spindle and 40 + 1 side mount tool change, we quickly found cycle times were reduced by 30%.

“These were our first 5-axis machines, but they were easier to use than I’d imagined,” enthuses Kieran. “They really worked for us. We use them for 5-sided machining; making multi-option parts, we finish them in much shorter lead times with a higher accuracy and precision.

“Following on from the success of our UMC-750s we have just installed the new Haas UMC-1000. We’re excited to see what we can do with the larger working envelope.

“We’ve also just installed our first Haas 4-axis rotary table and are looking forward to capitalizing on the advantages of lights out machining.”

“The Haas machines are invaluable. The increased spindle speed and rapids have reduced our cycle times by 50% and the spindle power is unrivalled. They cut aluminium constantly on full revs, as deep a cut as the spindle will allow. I haven’t found anything the spindle doesn’t have the power to cut.”

Christopher Doran